2.1 Terminal Block Precautions

In order to facilitate quick wiring, the EKU and EQU units of the M84 controller use PHOENIX lock screw type and reed type, reed type should be used according to the following specifications:

PHOENIX Reed Clamp Terminal Blocks

Wires and terminals used for wiring must meet the specifications in the following table:

Rigid wire minimum cross section |

0.2 mm2 |

|

Rigid conductor maximum cross section |

1.5 mm2 |

|

Flexible conductor minimum cross section |

0.2 mm2 |

|

Flexible conductor maximum cross section |

1 mm2 |

|

Flexible wire cross section, minimum cold head without insulation sleeve |

0.25 mm2 |

|

Flexible wire cross section, maximum cold head without insulation sleeve |

0.75 mm2 |

|

Flexible conductor cross section, minimum cold head with insulation sleeve |

0.25 mm2 |

|

Flexible conductor cross section, maximum cold head with insulation sleeve |

0.75 mm2 |

|

Minimum conductor cross section AWG |

24 |

|

Maximum conductor cross section AWG |

16 |

Observe the following specifications when wiring the machine to avoid improper operation of the terminal block.

1. |

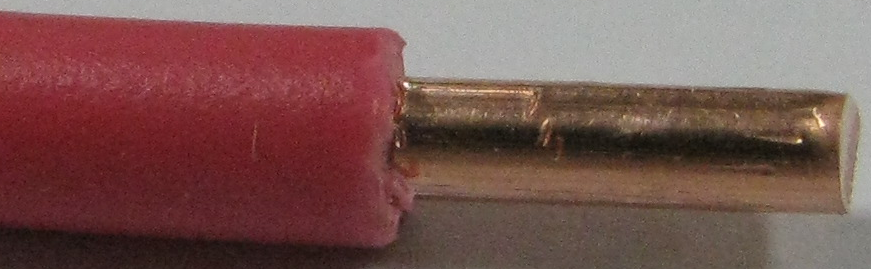

Use a special crimping tool when crimping the European terminal. The bad crimping tool will produce metal burrs at the front of the terminal, as shown in the figure below, this metal burr seizes the reed when it exits the wire from the terminal block, causing the wire to quit. |

Generate Metal Glitches Diagram

2. |

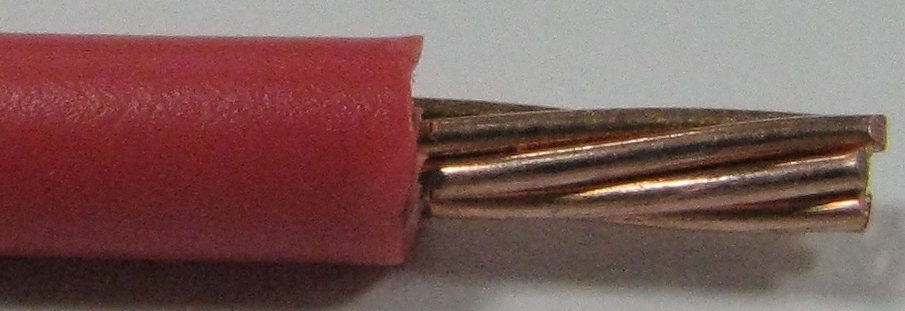

When exiting the wire, use a 4 mm flathead screwdriver to push the orange card holder down at an angle of 65° and remove the wire as shown below. |

Remove the Wire Schematic