4.5.5 G33: Threading

Format:

G33 X_F_

G33 Y_F_

G33 Z_F_

G33 X_Y_F_

G33 X_Z_F_

G33 Y_Z_F_

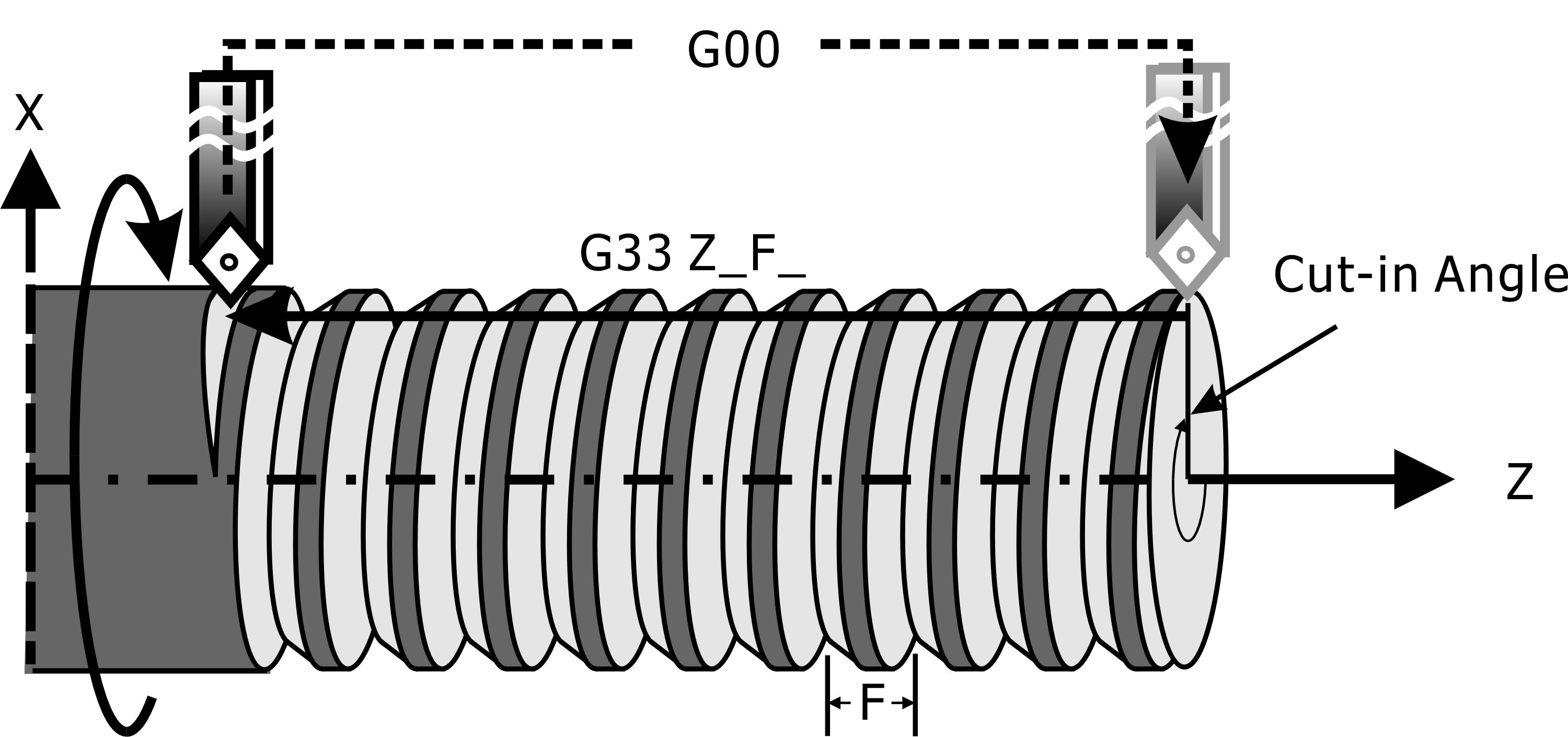

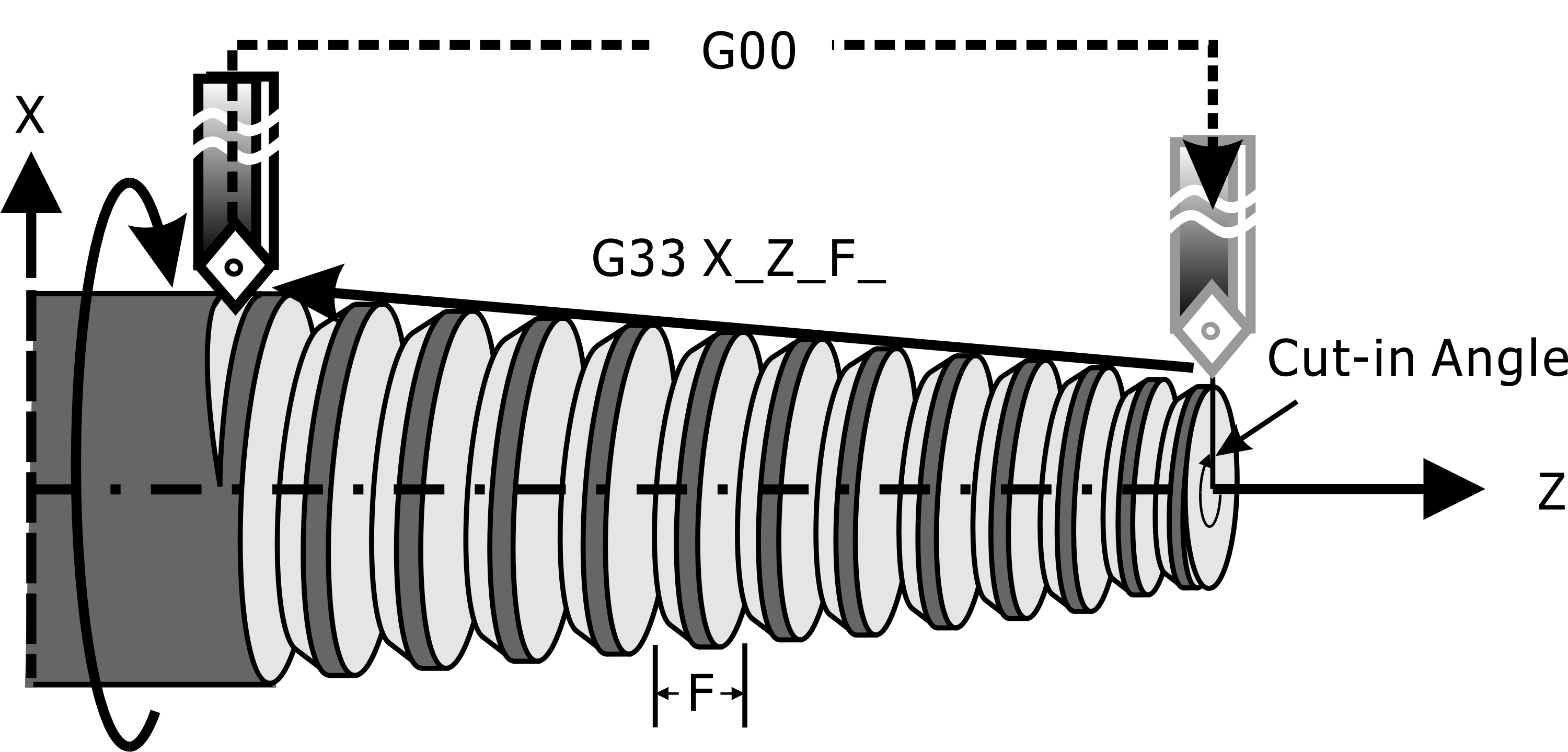

G33 needs to be used simultaneously with G95. G95 sets the F_ value to the feed speed per revolution. The tool cuts the surface of the workpiece in the direction of the X-axis, Y-axis, Z-axis, or the fourth axis according to the speed at which the spindle moves by F_ per revolution. When the G33 starts feeding in each axis, the feed is started only when the spindle rotates to a certain fixed angle (preset zero angle). Therefore, the G33 can be used for thread or a screw.

G33 Threading

G33 X_Z_F_ (Taper Threading)

Note 1: |

The G95 command must be given before the G33 command, and the machine spindle must have an Encoder to execute this command. |

Note 2: |

The dashed line returns the non-G33 command feed range of the moving part, which must be added by G00 command. |

Note 3: |

G33 can also make large-aperture thread cutting instructions. Most small-diameter internal threads are tapped with tapping instructions G74 and G84. However, because of the high tool cost of large-aperture thread, the use of an adjustable boring tool in conjunction with the G33 command can save costs. |