4.6.2 G37: Automatic Tool Length Measurement

Format:

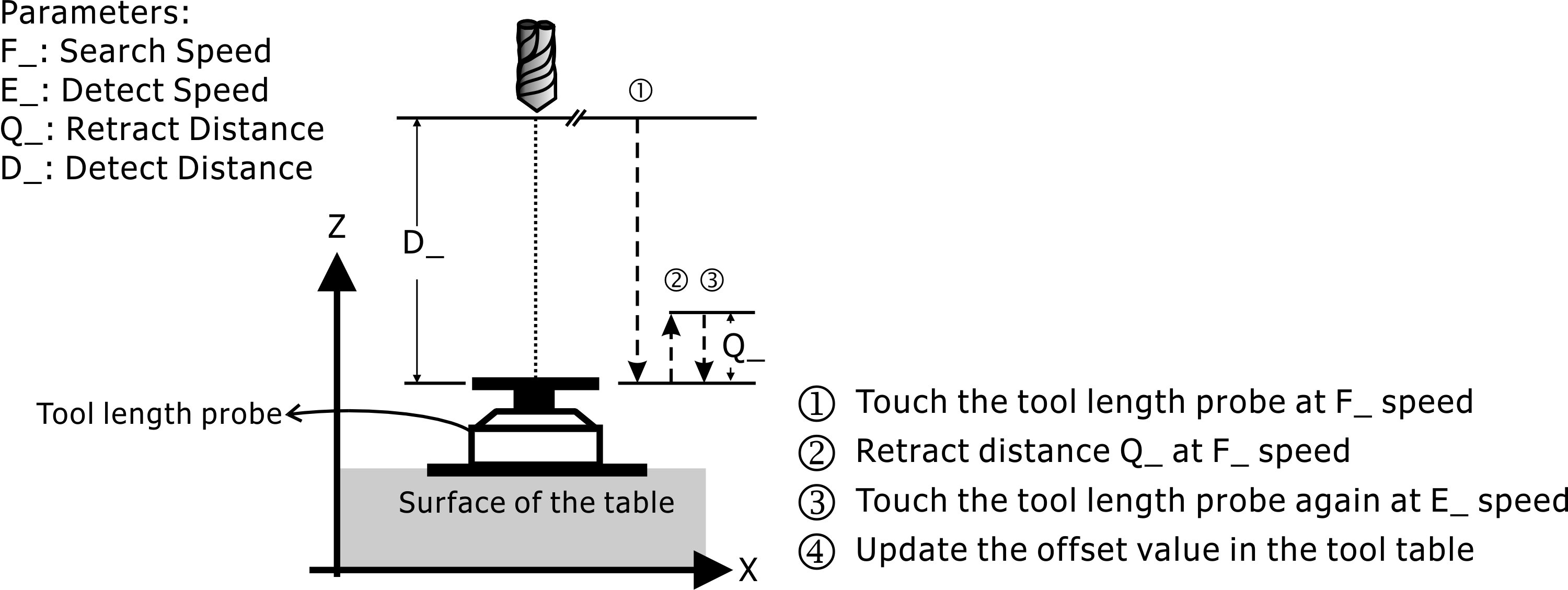

G37 Z_Q_D_F_E_

The G37 command allows the spindle to perform automatic tool length measurement in the axial direction in which it is mounted, and automatically replaces the tool length correction value in the tool list with the measured value. The Z value in this command refers to the mechanical absolute coordinate value at which the user wants the point of the blade to be in the axial direction when the tool tip touches the sensor. The expected mechanical position value and the actual mechanical position of the current point the difference between the two values is the calculated value obtained from this automatic measurement. The mathematical formula is as follows:

Expected mechanical position value (Z_) - Actual mechanical position value at this point = Calculated value from automatic measurement

The general spindle is mounted on the Z axis. The Z value is the Z axis value; if the spindle is mounted on the X or Y axis, this Z value is the value of the X or Y axis. If F_, E_, Q_, D_ and other items in the command are not set, the four items of move down speed, detecting speed, pull-up distance, and detection distance are preset in the "parameter→tool length measurement" item replace it.

Before using this instruction, be sure to confirm the following:

1. |

The machine is equipped with a tool length probe. |

2. |

The tool offset number (not H00) has been selected for the H_ command before this command. |

3. |

The measured tool has moved directly above the probe. |

The steps for automatic measurement are as follows:

1. |

Approach the probe at the feed rate of F_ until the tool tip touches the probe. If you do not touch the probe beyond the D_ distance, an alarm will be given and the machine will stop. |

2. |

Exit again at the speed of F_ to the distance from the probe Q_. |

3. |

Approach the sensor again with E_ until the tip touches the probe again. |

4. |

At this time, the controller will automatically calculate the axial position difference, and then this difference replaces the tool length compensation value of the tool compensation number in the original tool list. |

Note 1: |

The Z_ value must be set. The other values (F_, E_, Q_, D_) directly use the value set in the "tool length measurement" parameter. |

Note 2: |

The sign of the Q_ value is determined by the direction of movement of the prober. Generally, if Q_ is positive, the tool moves downwards close to the probe (negative direction of the Z axis); however, if Q_ is negative, the tool tip is up side mounted so that the Z-axis positive direction is looking for a probe. |

G37: Automatic Tool Length Measurement