4.9.3 G96/G97: Constant Surface Speed Control/Constant Surface Speed Control Cancellation

Format:

G96 S_

G97 S_

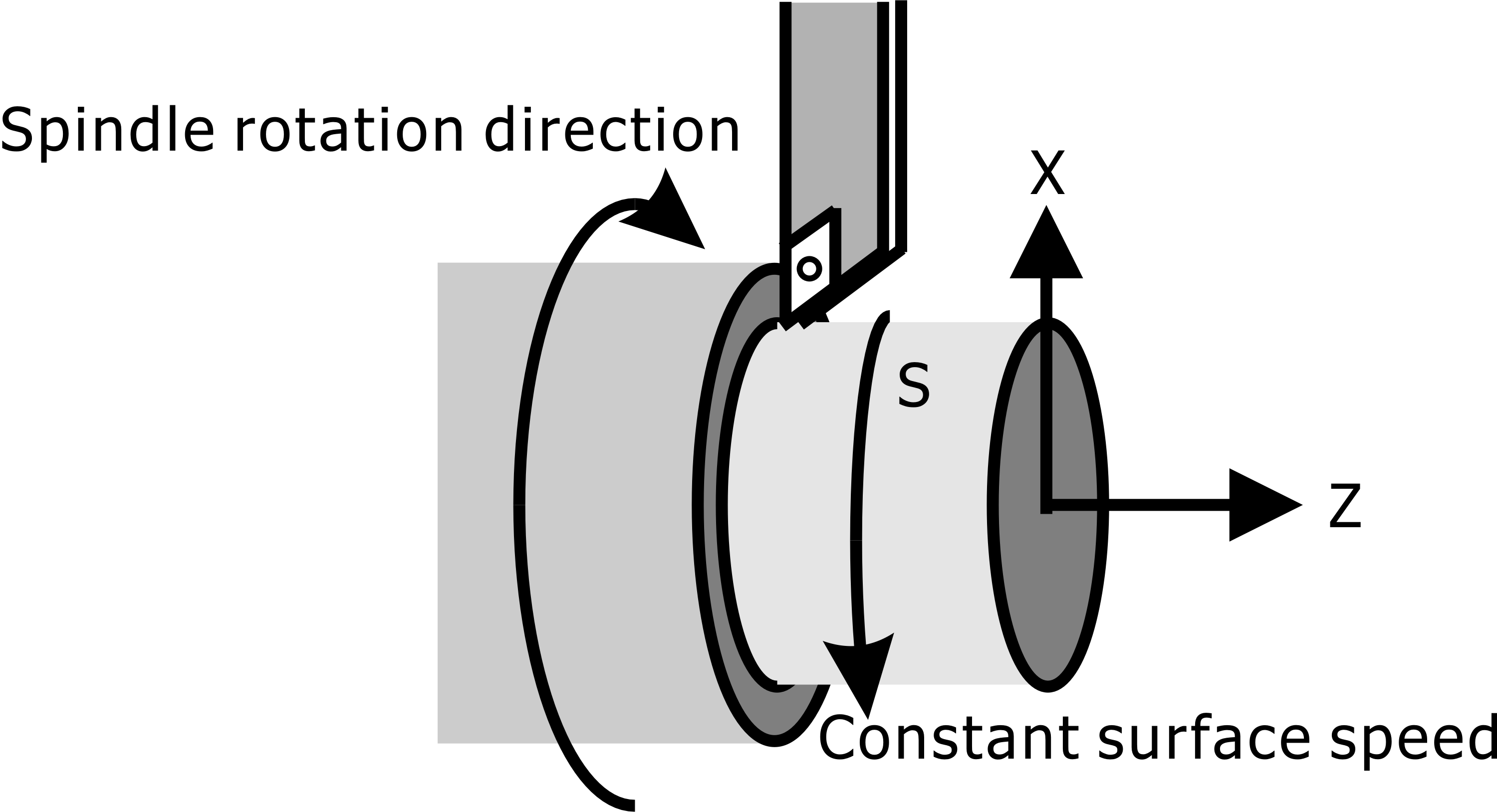

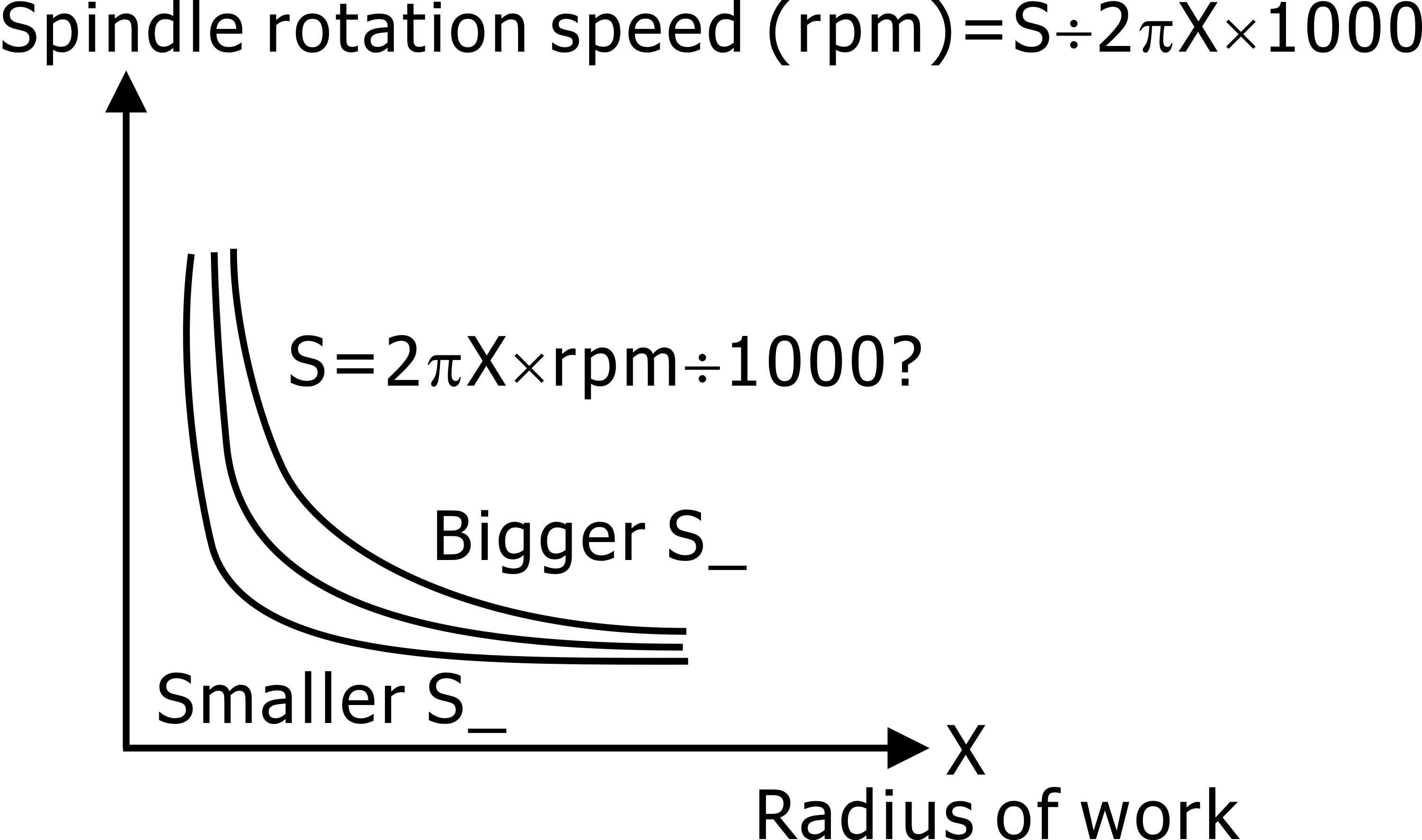

The constant surface speed control assumes that the Z-axis is the rotation axis of the workpiece, and the X-axis is the radius of the workpiece. Therefore, before performing the constant surface speed control, the X-axis coordinate zero must be set on the workpiece center axis to obtain the desired surface. Speed; The speed of the spindle will also gradually increase as the radius (X-axis) becomes smaller.

The G96 command enables constant surface speed control, which means that the workpiece is turned by the given surface feed speed S_ for surface cutting. The S_ can have up to five digits, its units are in m/min (metric meters per minute) in the metric system, and the inch system is in inches/min (inch per minute). The G97 command cancels the constant surface speed control and restores the S_ value to fixed speed control (rpm) per minute.

Constant Surface Speed Control

Relationship of Spindle Rotation Speed and Radius of Work