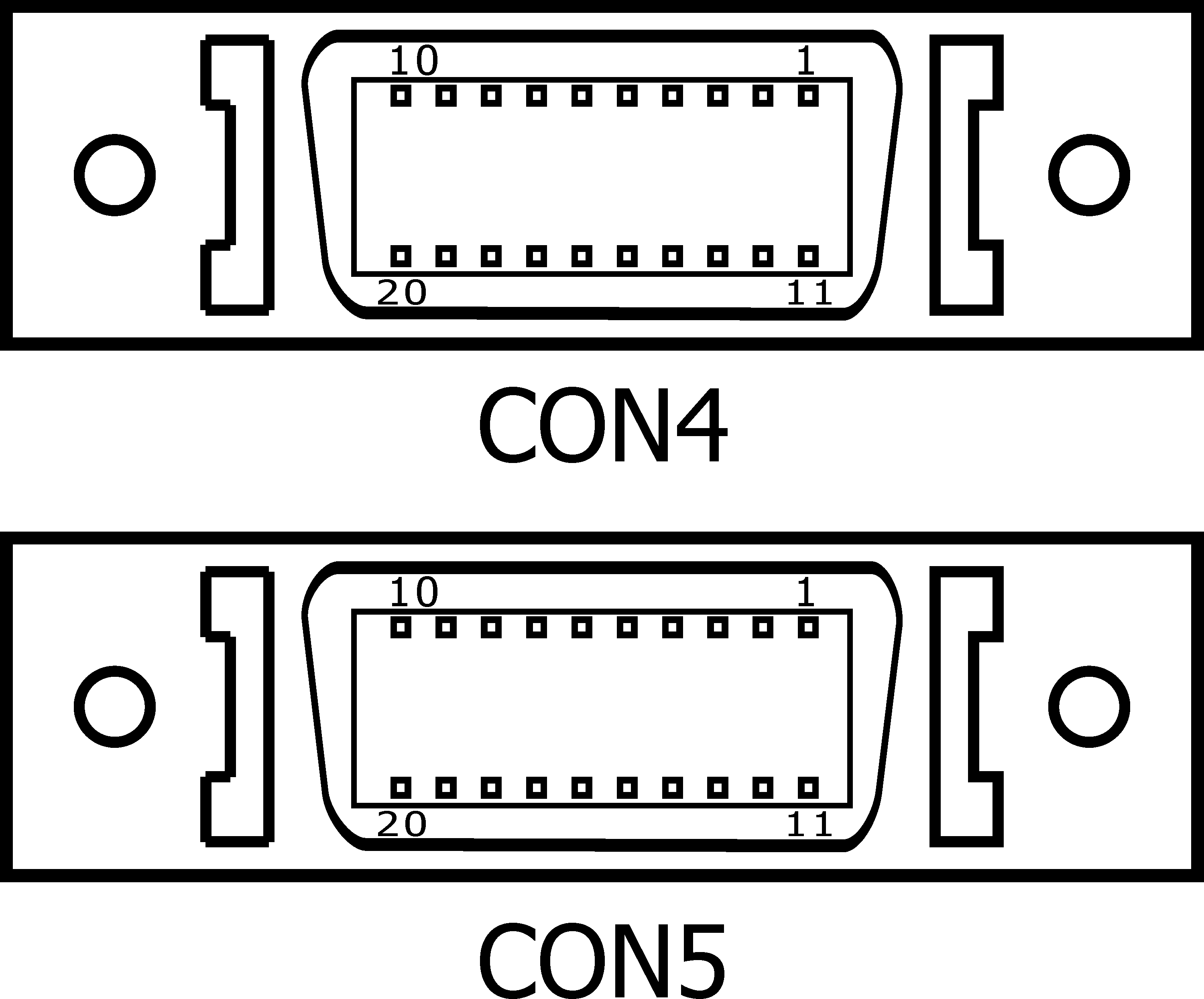

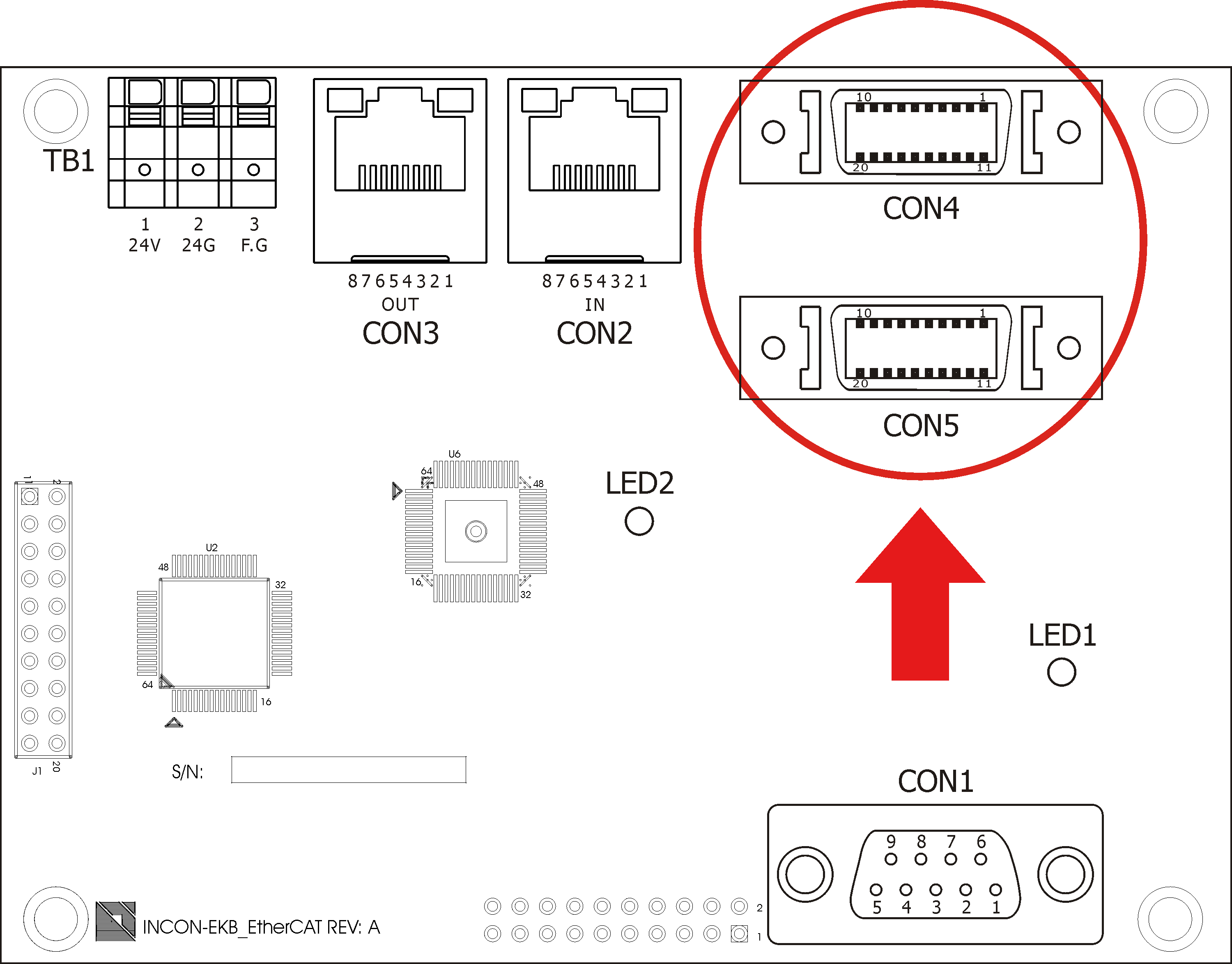

2.7.3 CON4, CON5: Handwheel Connector

Pin |

Definition |

Explain |

||||

1 |

Axis selection input point 1 |

Through PLC set the corresponding axis |

||||

2 |

Axis selection input point 2 |

Through PLC set the corresponding axis |

||||

3 |

Axis selection input point 3 |

Through PLC set the corresponding axis |

||||

4 |

Axis selection input point 4 |

Through PLC set the corresponding axis |

||||

5 |

Axis selection input point 5 |

Through PLC set the corresponding axis |

||||

6 |

Axis selection input point 6 |

Through PLC set the corresponding axis |

||||

7 |

A+ |

Handwheel signal A+ input |

||||

8 |

A- |

Handwheel signal A- input |

||||

9 |

B+ |

Handwheel signal B+ input |

||||

10 |

B- |

Handwheel signal B- input |

||||

11 |

Z+ |

Handwheel signal Z+ input (General handwheel without this signal) |

||||

12 |

Z- |

Handwheel signal Z- input (General handwheel without this signal) |

||||

13 |

Handwheel step width input point 1 |

Through PLC set the corresponding magnification |

||||

14 |

Handwheel step width input point 2 |

Through PLC set the corresponding magnification |

||||

15 |

Handwheel step width input point 3 |

Through PLC set the corresponding magnification |

||||

16 |

n/c |

Empty |

||||

17 |

VI |

+24V input power from external I/O, the power cannot use the same power supplier as EKU. |

||||

18 |

VG |

|

||||

19 |

5V |

Provide handwheel 5V power (Power: 1W) |

||||

20 |

5V GND |

Provide handwheel power 5V power ground (Power: 1W) |

CON4, CON5 Handwheel Connector

CON4, CON5 Placement Drawing