4.1.1.3 VTO

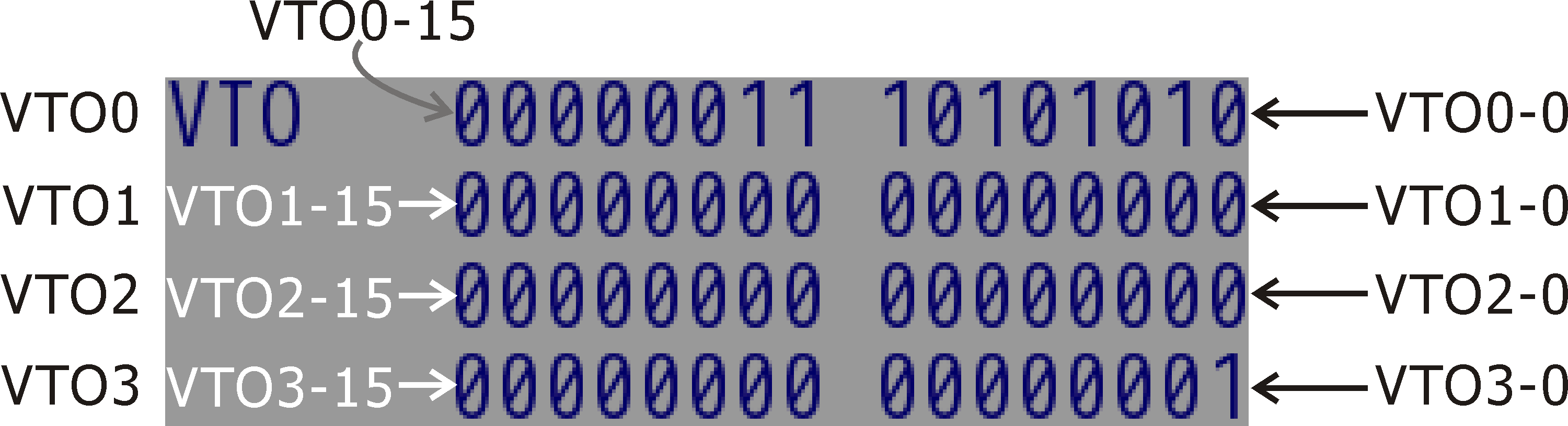

VTO is a virtual output point, with NC and PLC as communication bridge, GDI (PLC's external output), GDO (PLC output), SPI all can be VTO output, VTO output point will increase due to PLC function increase, each VTO is form via 16 bits, the left's [ 0 ]~[ 4 ] represent VTO0, VTO1, VTO2, VTO3, VTO4.

VTO Page

Below table explain how system detection image VTO correspond to PLC_VTO.H each VTO bit and its definition. Each VTO bit detail explain, please refer to INCON-M84/M86/M86R PLC Manual.

VTO |

Corresponding VTO bit |

Definition |

[0].0 |

plc.vto0.bit.fvov0 |

Feed rate override percentage bit 0 |

[0].1 |

plc.vto0.bit.fvov1 |

Feed rate override percentage bit 1 |

[0].2 |

plc.vto0.bit.fvov2 |

Feed rate override percentage bit 2 |

[0].3 |

plc.vto0.bit.fvov3 |

Feed rate override percentage bit 3 |

[0].4 |

plc.vto0.bit.jgov0 |

Jog override percentage bit 0 |

[0].5 |

plc.vto0.bit.jgov1 |

Jog override percentage bit 1 |

[0].6 |

plc.vto0.bit.jgov2 |

Jog override percentage bit 2 |

[0].7 |

plc.vto0.bit.jgov3 |

Jog override percentage bit 3 |

[0].8 |

plc.vto0.bit.G0ov0 |

G00 override percentage bit 0 |

[0].9 |

plc.vto0.bit.G0ov1 |

G00 override percentage bit 1 |

[0].A |

plc.vto0.bit.clsrt |

Program cycle start |

[0].B |

plc.vto0.bit.fhold |

Program feed hold |

[0].C |

plc.vto0.bit.emgsp |

Emergency stop |

[0].D |

plc.vto0.bit.probe |

Tool probe signal input |

[0].E |

plc.vto0.bit.iwst0 |

INC /hand wheel step width bit 0 |

[0].F |

plc.vto0.bit.iwst1 |

INC /hand wheel step width bit 1 |

VTO |

Corresponding VTO bit |

Definition |

[1].0 |

plc.vto1.bit.xhome |

X axis external homing input |

[1].1 |

plc.vto1.bit.yhome |

Y axis external homing input |

[1].2 |

plc.vto1.bit.zhome |

Z axis external homing input |

[1].3 |

plc.vto1.bit.ahome |

A axis external homing input |

[1].4 |

plc.vto1.bit.wlAx0 |

Hand wheel axis selection bit 0 |

[1].5 |

plc.vto1.bit.wlAx1 |

Hand wheel axis selection bit 1 |

[1].6 |

plc.vto1.bit.mMod0 |

Manual mode bit 0 |

[1].7 |

plc.vto1.bit.mMod1 |

Manual mode bit 1 |

[1].8 |

plc.vto1.bit.xovtr |

X axis over travel |

[1].9 |

plc.vto1.bit.yovtr |

Y axis over travel |

[1].A |

plc.vto1.bit.zovtr |

Z axis over travel |

[1].B |

plc.vto1.bit.aovtr |

A axis over travel |

[1].C |

plc.vto1.bit.wlOff |

Handwheel close |

[1].D |

plc.vto1.bit.teach |

Tech in input |

[1].E |

plc.vto1.bit.athom |

Auto homing |

[1].F |

plc.vto1.bit.ptpgm |

Program editing protection |

VTO |

Corresponding VTO bit |

Definition |

[2].0 |

plc.vto2.bit.skp31 |

G31 input |

[2].1 |

plc.vto2.bit.jogsp |

From PLC appoint Jog speed |

[2].2 |

plc.vto2.bit.svpar |

Save PLC parameter |

[2].3 |

plc.vto2.bit.nosft |

Close soft limit |

[2].4 |

plc.vto2.bit.rgsiv |

Rigid tapping spindle output voltage reverse |

[2].5 |

plc.vto2.bit.sstep |

PLC sub program single block execution |

[2].6 |

plc.vto2.bit.cprad |

Calculation radius |

[2].7 |

plc.vto2.bit.zcmpl |

Z axis clamp movement |

[2].8 |

plc.vto2.bit.emgmv |

Emergency movement axis |

[2].9 |

plc.vto2.bit.emvsp |

Stop emergency happening movement axis |

[2].A |

plc.vto2.bit.tlcmp |

Write tool compensation table |

[2].B |

plc.vto2.bit.wlax2 |

Hand wheel axis selection bit 2 |

[2].C |

plc.vto2.bit.bhome |

B axis external homing input |

[2].D |

plc.vto2.bit.chome |

C axis external homing input |

[2].E |

plc.vto2.bit.bovtr |

B axis over travel |

[2].F |

plc.vto2.bit.covtr |

C axis over travel |

VTO |

Corresponding VTO bit |

Definition |

[3].0 |

plc.vto3.bit.Vis4X |

CNC controller software to be 4.xx version or above |

[3].1 |

plc.vto3.bit.HisVM |

CNC controller hardware is VM module |

[3].2 |

plc.vto3.bit.V4spc |

CNC controller through plc.axisPmySindle.da control main spindle voltage |

[3].3 |

plc.vto3.bit.jogct |

External appoint the input point to replace pre-set Jog input |

[3].4 |

plc.vto3.bit.HmOnc |

Do one homing, when system has done homing, when again do homing directly move to machine home |

[3].5 |

plc.vto3.bit.lnG00 |

G00 linear position |

[3].6 |

plc.vto3.bit.ddmt0 |

Simultaneous axis select bit 0 |

[3].7 |

plc.vto3.bit.ddmt1 |

Simultaneous axis select bit 1 |

[3].8 |

plc.vto3.bit.alwmp |

Every machine enter parameter requires password input |

[3].9 |

plc.vto3.bit.spdsp |

DNC show 7 lines, CNC controller image bottom right corner show machine coordinate, program coordinate, corresponding coordinate, remaining info |

[3].A |

plc.vto3.bit.swMan |

CNC controller shifts to manual mode |

[3].B |

plc.vto3.bit.whs1k |

Hand wheel step width X1000 |

[3].C |

plc.vto3.bit.rgsda |

When doing rigid tapping from NC control to spindle speed |

[3].D |

plc.vto3.bit.mstin |

System reserve |

[3].E |

plc.vto3.bit.mstfi |

System reserve |

[3].F |

plc.vto3.bit.stfov |

Use new advance override management style |

VTO |

Corresponding VTO bit |

Definition |

[4].0 |

plc.vto3.bit.zofnn |

Check G54~G59 Z value can't be negative |

[4].1 |

plc.vto3.bit.toHDL |

Is Servo close shift to manual mode |

[4].2 |

plc.vto3.bit.hdmpa |

Hidden part of machine parameter (high speed high accuracy parameter) |

[4].3 |

plc.vto3.bit.nedlg |

Is manual mode showing wrong signal in dialog box |

[4].4 |

plc.vto3.bit.ghov0 |

G00 16 section override mode speed override adjustment bit 0 |

[4].5 |

plc.vto3.bit.ghov1 |

G00 16 section override mode speed override adjustment bit 1 |

[4].6 |

plc.vto3.bit.ghov2 |

G00 16 section override mode speed override adjustment bit 2 |

[4].7 |

plc.vto3.bit.ghov3 |

G00 16 section override mode speed override adjustment bit 3 |

[4].8 |

plc.vto3.bit.ghovd |

Choose G00 16 section override mode |

[4].9 |

plc.vto3.bit.pcent |

Speed override use 1% unit |

[4].A |

plc.vto3.bit.sk31a |

G31 command if surpass order distance didn't detect the SKIP signal, there will be warning |

[4].B |

plc.vto3.bit.g0hld |

Execution program will stop at G00 |

[4].C |

plc.vto3.bit.ngkyu |

System don't manage GKYU signal |

[4].D |

plc.vto3.bit.nextp |

CNC controller status window, left distance will turn into the next single target |

[4].E |

plc.vto3.bit.adryn |

Advance dry run |

[4].F |

plc.vto3.bit.clsrd |

Tapping spindle close loop control |