4.1.1.4 Others

Diagnosis Page 1 Down Half Page

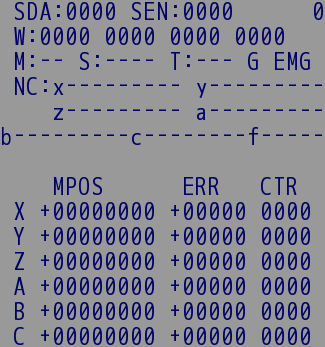

- SDA: SDA showing the current voltage output of spindle, range from 07FF~F801 represent CNC controller spindle analogy voltage +10V~-10V.

- SEN: Spindle encoder feedback calculate value, with hex for showing.

- W 0000 0000 0000 0000: Handwheel encoder time calculation value, with hex showing.

- M: -- S: ----T: ---: This item showing M, S and T code info, this info will be removed after M, S and T code is complete. M, S, and T code through NC sends to PLC, through PLC conduct M, S and T code management. When PLC has been finished dealing, sends execution complete signal to NC, after NC received complete flog, it will finished M, S and T code and continue to execute the next program.

- G: When NC is executing axis movement of the G code status, when G code is executing it will be highlighted.

- EMG: Showing EMG exercising or dissolves status, when EMG is happening it would be highlighted.

- NC: x------- y------- z------- a------- b------- c------- f-------: PLC sends to NC movement info, this line shows the purpose of each axis, machine positive value and motion speed.

- MPOS: Showing each axis' machine positive value.

- ERR: Showing each axis' current servo following error value. If the value is larger than each axis' largest following error value, the system will send out warning and stop axis movement.

- CTR: Showing each axis' encoder's calculated value. According to encoder's positive and negative spin, increase and decrease the calculated number.