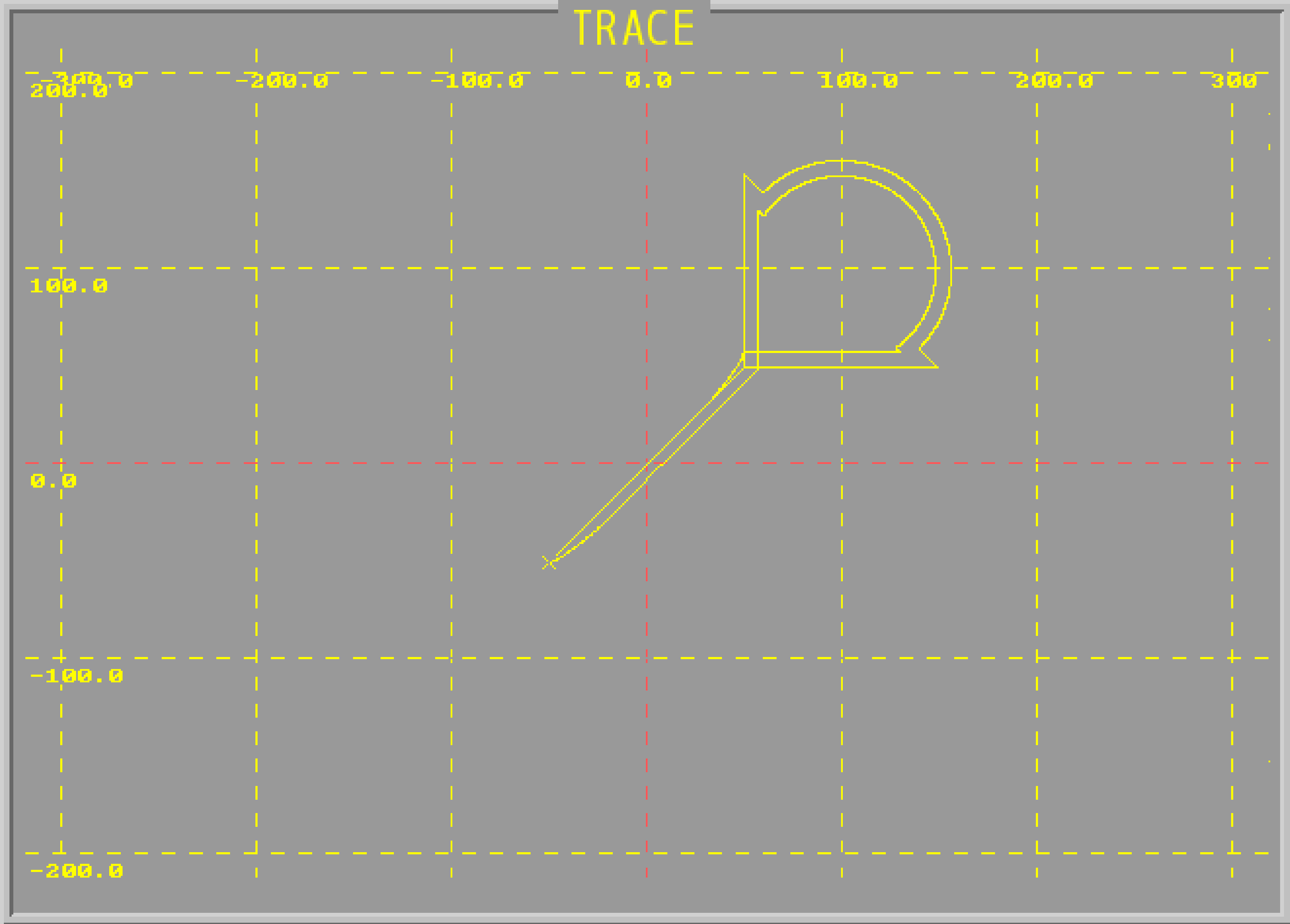

4.15.4 Example of Tool Radius Compensation: G41/G42

- SAMPL41.CNC

;First set parameter

;parameter→tool compensation graph

;tool number 1 radius compensation =2.5 mm

;

;The formal path begins

G17 G90

G92 X0 Y0 Z0

G0 X100. Y100.

M97 P1041 ;calling subprogram O1041

G0 X0 Y0

M01 ;formal path end

;

;Tool radius left compensation started

H1 ;choose first tool table

G41 G0 X100. Y100.

M97 P1041 ;calling subprogram O1041

G40 G0 X0 Y0 ;end G41

M30 ;program end

;

O1041 ; subprogram

G01 X200. F1500.

X190. Y110.

G03 X110.Y190.I-40.J40.

G01 X100. Y200.

Y100.

M99 ; subprogram end

Example of Tool Radius Compensation: G41

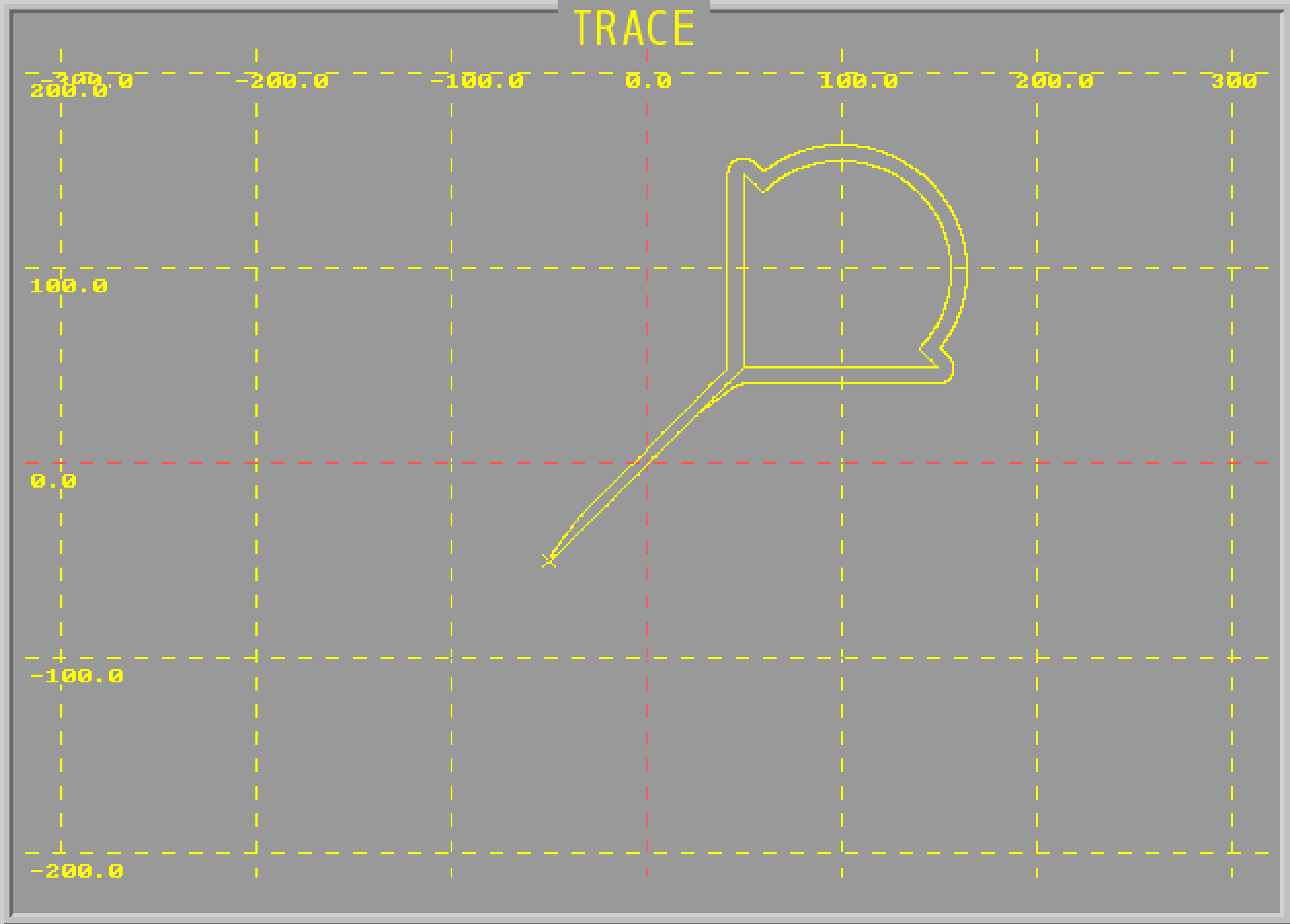

- SAMPL42.CNC

;First set parameter

;parameter->tool table

;Tool nimber 1 radius = 2.5 mm

;The formal path begins

G17 G90

G92 X0 Y0 Z0

G0 X100. Y100.

M97 P1042 ;calling subprogram O1042

G0 X0 Y0

M01 ;formal path end

;

;Tool right compensate start

H1 ;tool 1 compensation from tool table

G42 G0 X100. Y100.

M97 P1042 ;calling calling subprogram O1042

G40 G0 X0 Y0 ;end G42

M30 ;program end

;

O1042 ;subprogram

G01 X200. F1500.

X190. Y110.

G03 X110.Y190.I-40.J40.

G01 X100. Y200.

Y100.

M99 ;subprogram end

Example of Tool Radius Compensation: G42