3.12.2.1 Check Item

- 1/10 Micron SU: If this item is checked, system unit will be calculated to four decimal places.

Note: |

When switching 1 Micron SU or 1/10 Micron SU, the following user parameter and machine parameters will be changed. |

User parameter |

|

1 |

Coordinate offset table |

2 |

Reference Position |

3 |

Tool Table |

4 |

Tool Length Measurement→Retract Distance/Detect Distance |

5 |

Cancycle Parameters→Cut In Retract Length |

6 |

G158 Coordinate Offsets |

7 |

Rotation Angle→Angle |

8 |

Extra G54 Coordinate Offsets |

Machine parameters |

|

Axis |

Backlash/ Sub Backlash |

Index Offset |

|

Positive Soft Limit |

|

Negative Soft Limit |

|

Machine Pos Preset |

|

Follow Axis Offset |

|

G10.4 Offset |

|

Pitch error compensation |

|

Reverse pitch error compensation |

|

Spline Interpolation |

|

5 Axis Rotary Mechanism |

|

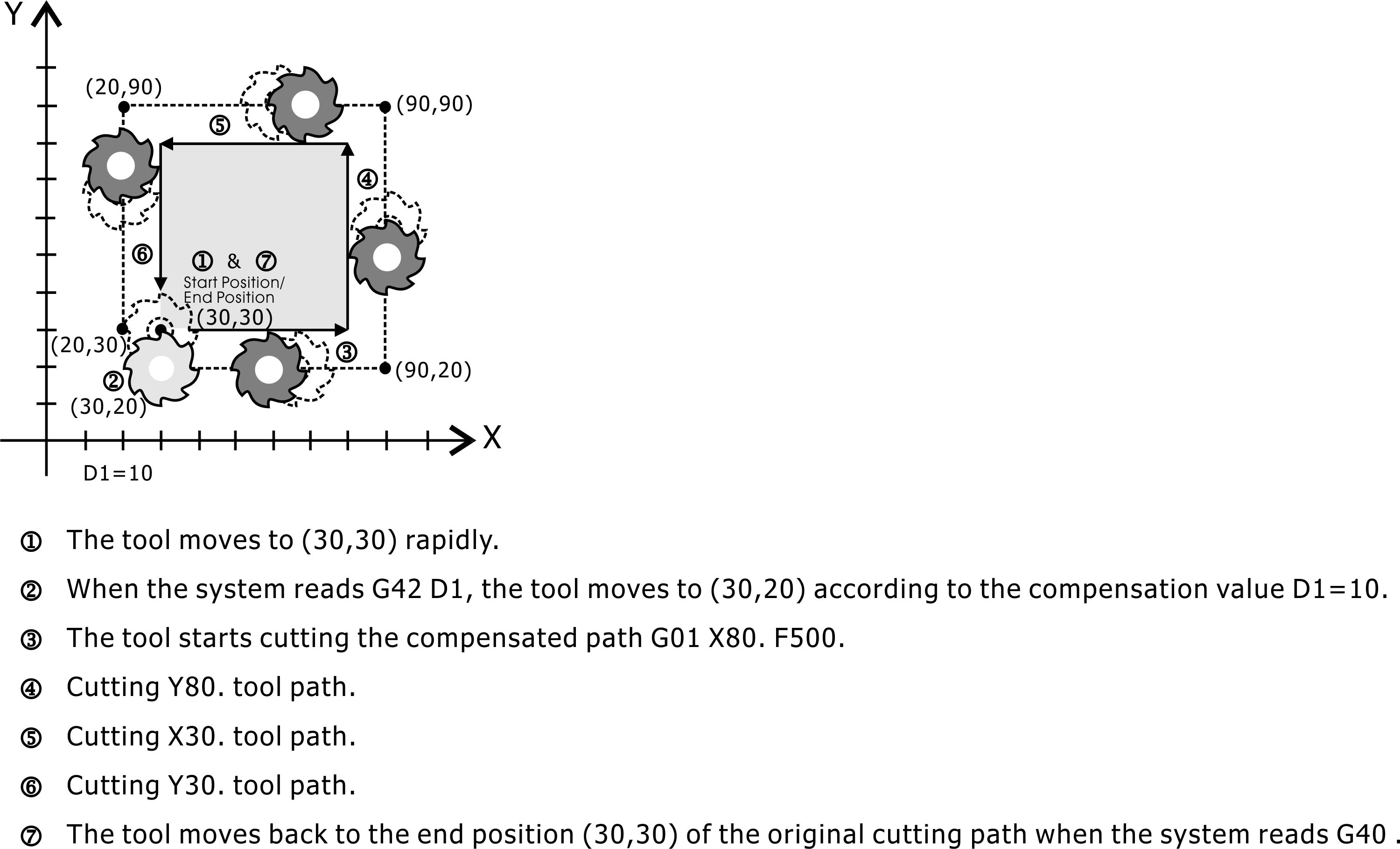

- EIA Tool Comp Mode: If choosing this item, when the system read the G41/G42 command, the tool automatically moves to the starting point of the tool path compensation cutting path based on the compensation value D, then start radius compensation path cutting. The tool returns to the end of the original cutting path. Example and explain is as below:

Sample program:

G00 X0. Y0.

X30.Y30.

G42 D1

G01 X80.F500.

Y80.

X30.

Y30.

G40

M30

Explain:

Tool quickly move to (30, 30), after it read G42 D1 (initiate tool compensation command), according to D1=10 starting from (30, 30) move to tool compensation route origin point (30, 20), then start executing G01 X80. F500 route cutting, until it read G40 (tool compensation cancel command), tool return to original cutting final spot (30, 30), cutting route is as following:

EIA Tool Comp Mode

- Find Feed: Choose this item. When CNC controller is working, it uses a more precise Interpolation method.

- Find Backlash:

(1) |

Please be aware: When choosing this item, must choose the 1/10 um SU or precision feed item, before this function be used. |

(2) |

When precision backlash has not been chosen, if the value of the second backlash dialog box is 0, the system would use the backlash column's setting; and backlash and second backlash setting value unit is 1 μm. |

(3) |

When choosing this item, backlash and second backlash's setting value need to be set separate. (When secondary backlash column's value is 0, the system would not automatically use the setting within the backlash column.) |

(4) |

When Precision backlash item has been chosen, backlash and second backlash setting value is 1/10 μm. |

Savetime Cancycle Mcode:

Savetime Cancycle Mcode:

If chosen this item, within the continue can cycle command, it will save time handling the spindle start M code, thus start spindle at the end of N hole, only after moving to the N+1 hole will it detect whether the M code is complete, instead of detecting that the M code is complete and move to N+1 hole, after N hole work is completed.

Please be aware, if this item has been chosen, the PLC program need to be rewritten as:

if(plc.mCode.flag && !plc.mCode.finish){

switch(plc.mCode.data){

.... // m code processing

}

}

Cannot write PLC according to the following method:

if(plc.mCode.flag){

switch(plc.mCode.data){

.... // m code processing

}

}

Can cycle that can help save time include: G88、G87、G76、G86.

- Plc with Type B Macro: If this item is chosen, when CNC controller is executing PLC, It will use macro mode B. If this item is not chosen, CNC controller will use micro mode A. About macro mode B, please refer to INCON-M84/M86/M86R User Manual.

No Accel B Backlash as G168: M86R CNC controller in G168 mode will be based on the parameters of the (INCON-M86R Suitable Use) 5 Axis Rotary Mechanism to compensate for the rotation mechanism assembly error, for example the formation of the turntable-turntable, let C axis continue to rotate under G168 mode, at this point the tilt axis of X, Y will continue to conduct error adjustment according offset parameter of X or Y of five axis rotary mechanism. In this case, if we add X axis, Y axis acceleration backlash compensation and the X axis, Y axis acceleration backlash compensation value to the X axis, Y axis and backlash compensation time is too long, will cause unusual shaking sound within X axis and Y axis, will also cause the work item to have a rough surface, the item can be used and don't use the axial acceleration backlash compensation.

No Accel B Backlash as G168: M86R CNC controller in G168 mode will be based on the parameters of the (INCON-M86R Suitable Use) 5 Axis Rotary Mechanism to compensate for the rotation mechanism assembly error, for example the formation of the turntable-turntable, let C axis continue to rotate under G168 mode, at this point the tilt axis of X, Y will continue to conduct error adjustment according offset parameter of X or Y of five axis rotary mechanism. In this case, if we add X axis, Y axis acceleration backlash compensation and the X axis, Y axis acceleration backlash compensation value to the X axis, Y axis and backlash compensation time is too long, will cause unusual shaking sound within X axis and Y axis, will also cause the work item to have a rough surface, the item can be used and don't use the axial acceleration backlash compensation. Match G168G169 offset: If this item is chosen, the G158/G168 mode will use the same coordinate offset as the G169 mode.

Match G168G169 offset: If this item is chosen, the G158/G168 mode will use the same coordinate offset as the G169 mode. Always use G178: If this item is checked, once G168 mode is enabled, no matter G178 is declared in program or not, G00 positioning can run in 5 axis program space.

Always use G178: If this item is checked, once G168 mode is enabled, no matter G178 is declared in program or not, G00 positioning can run in 5 axis program space.