7.3 Backlash Measurement of Laser Instrument and Pitch Error Compensation

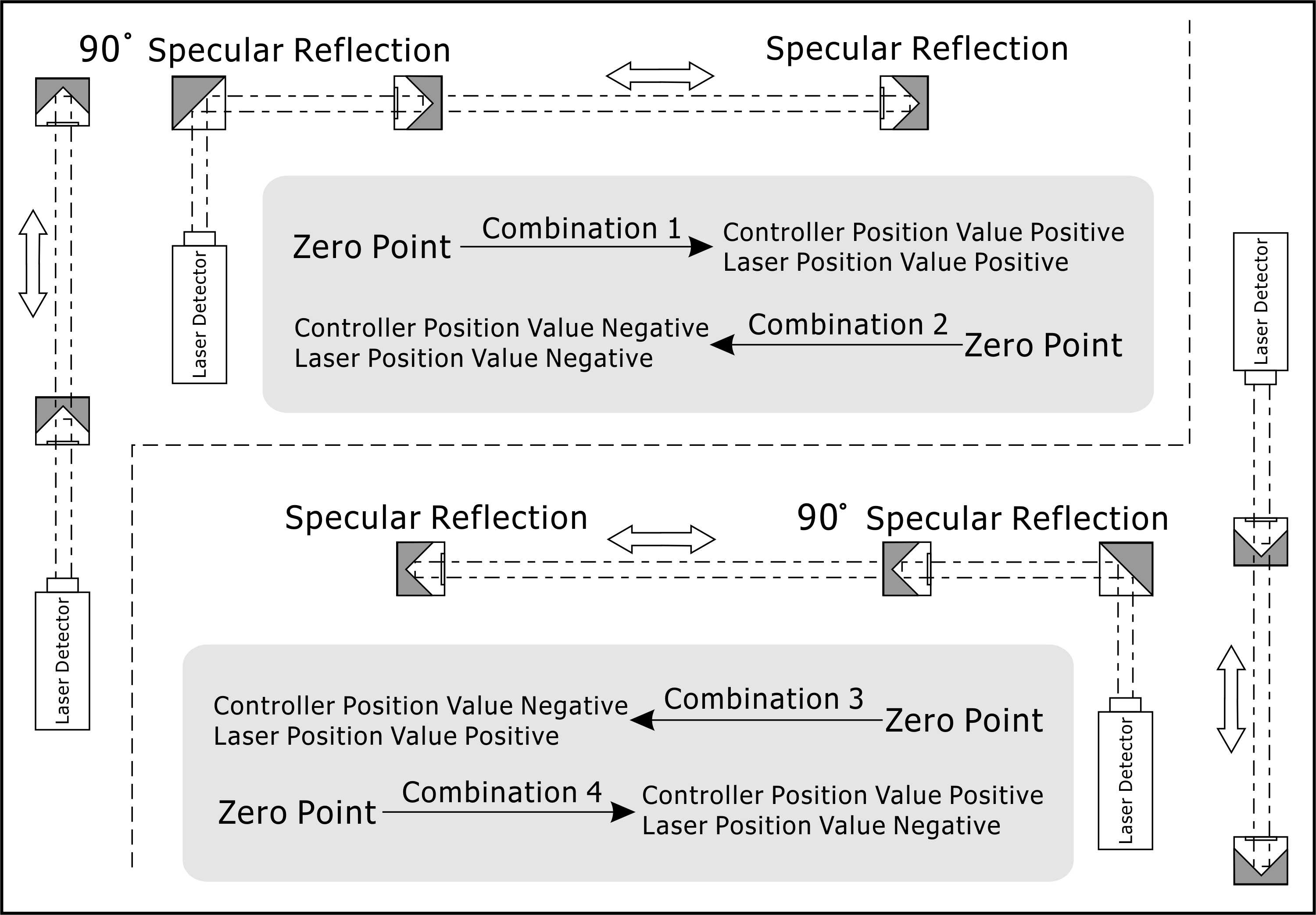

Laser backlash measurement and screw pitch error's method, according to laser measurement and reflection mirror's installation method and home's position we can see the following four.

Laser Measurement, Reflection Glass and Home's Relation

The CNC controller used' position value within the graph above is machine position value. Within laser measurement side, usually provide parameter to chose between positive and negative value, while in partnership with INCON-M84/M86/M86R, laser measurement coordinate's +, − sign must be same as that of CNC controller and machine, what that mean is the CNC controller's machine position value and laser measurement and showing position value must be same (must all be positive or negative). Before conducting measurement do the following:

- Each axis motor's servo character is complete (e.g. loop gain, notch filter, must be balance with each axis). If the motor's servo got Auto-tune function, please close down and don't use it.

- Each axis' software limit for now won't be use, start working again after finishing the measurement. Each axis' parameter's coordinate offset, must be clear to zero.

Also, before measurement every time, you must conduct homing for such axis, only then can the measurement be accurate, provide with auto laser backlash measurement and screw error, before measuring INCON-M84/M86/M86R need to execute program require for measurement.