4.13.18.1 4th-axis Rotation Angle On

Format:

G71.01 A_E_R_

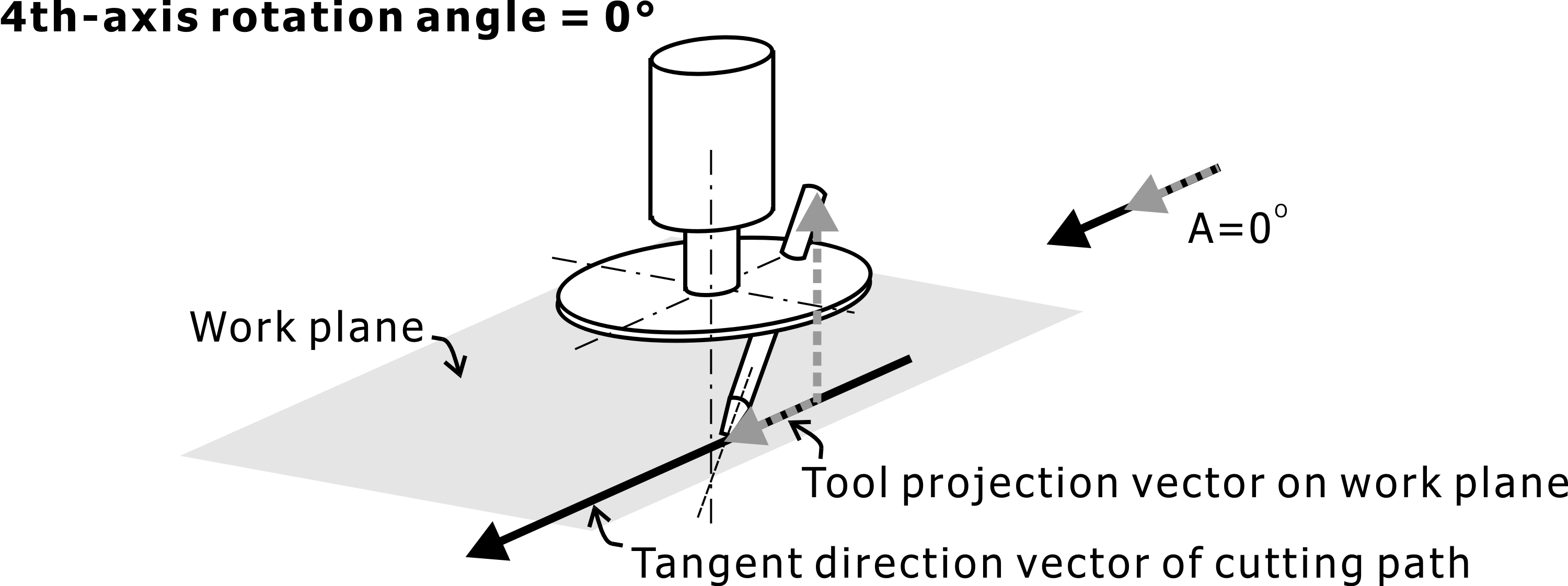

In this instruction, A_ defines the starting tilt angle. In the cutting path, the projection vector of the nozzle on the work plane will always maintain this tilt angle with the tangential direction of the cutting path. If this value is not given, it is regarded as zero.

In this instruction, A is the name of the fourth axis. If the fourth axis is named C, the instruction must be modified to G71.01 C_E_R_; otherwise, an error instruction message will appear.

Note: The angle 90° in the program is expressed as 90.000.

The starting tilt angle of the fourth axis is 0°. If A_ is not given in the program, it is regarded as zero.

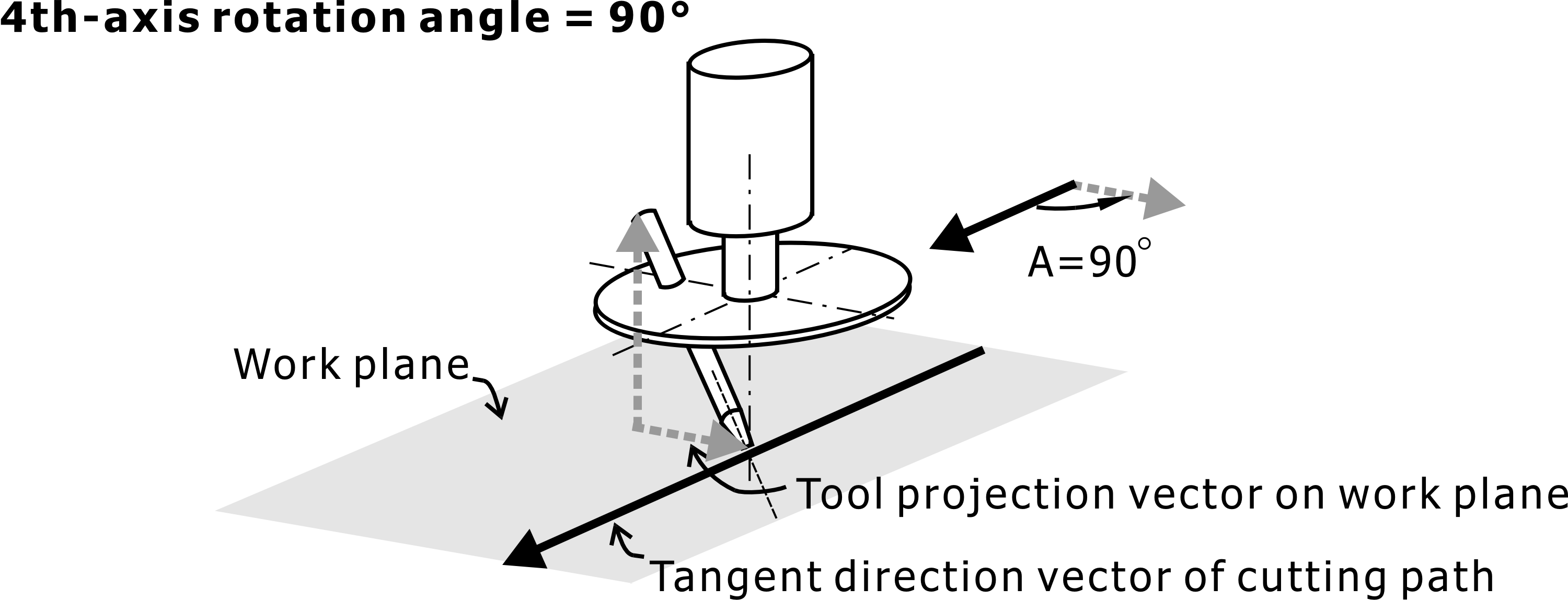

The fourth axis shift angle is 90°

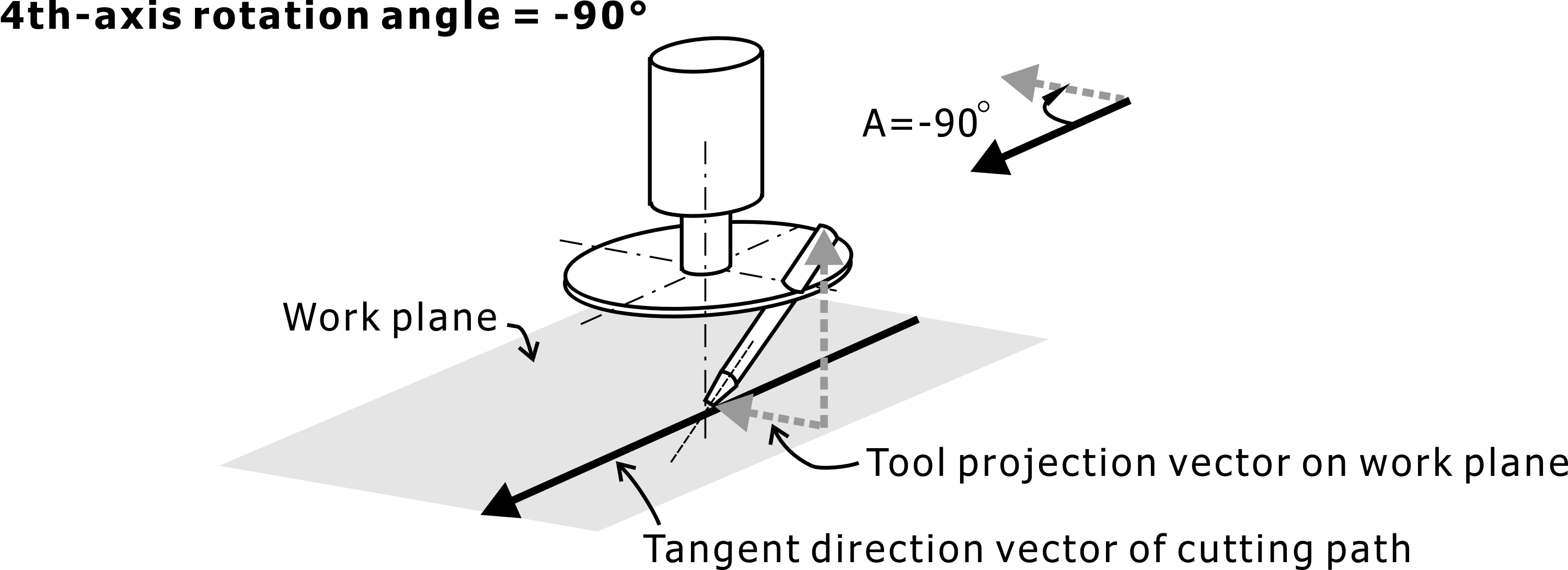

The fourth axis shift angle is -90°

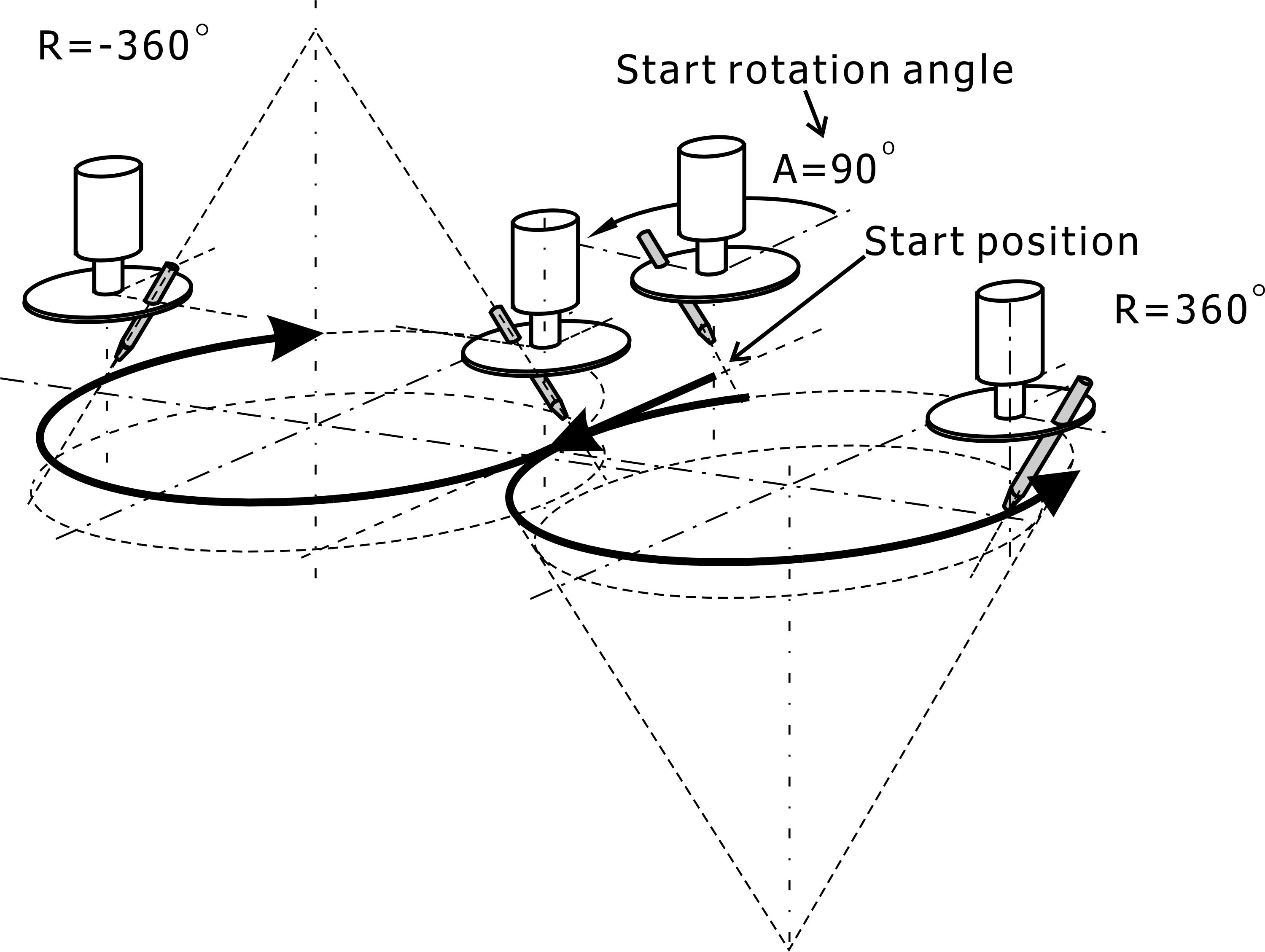

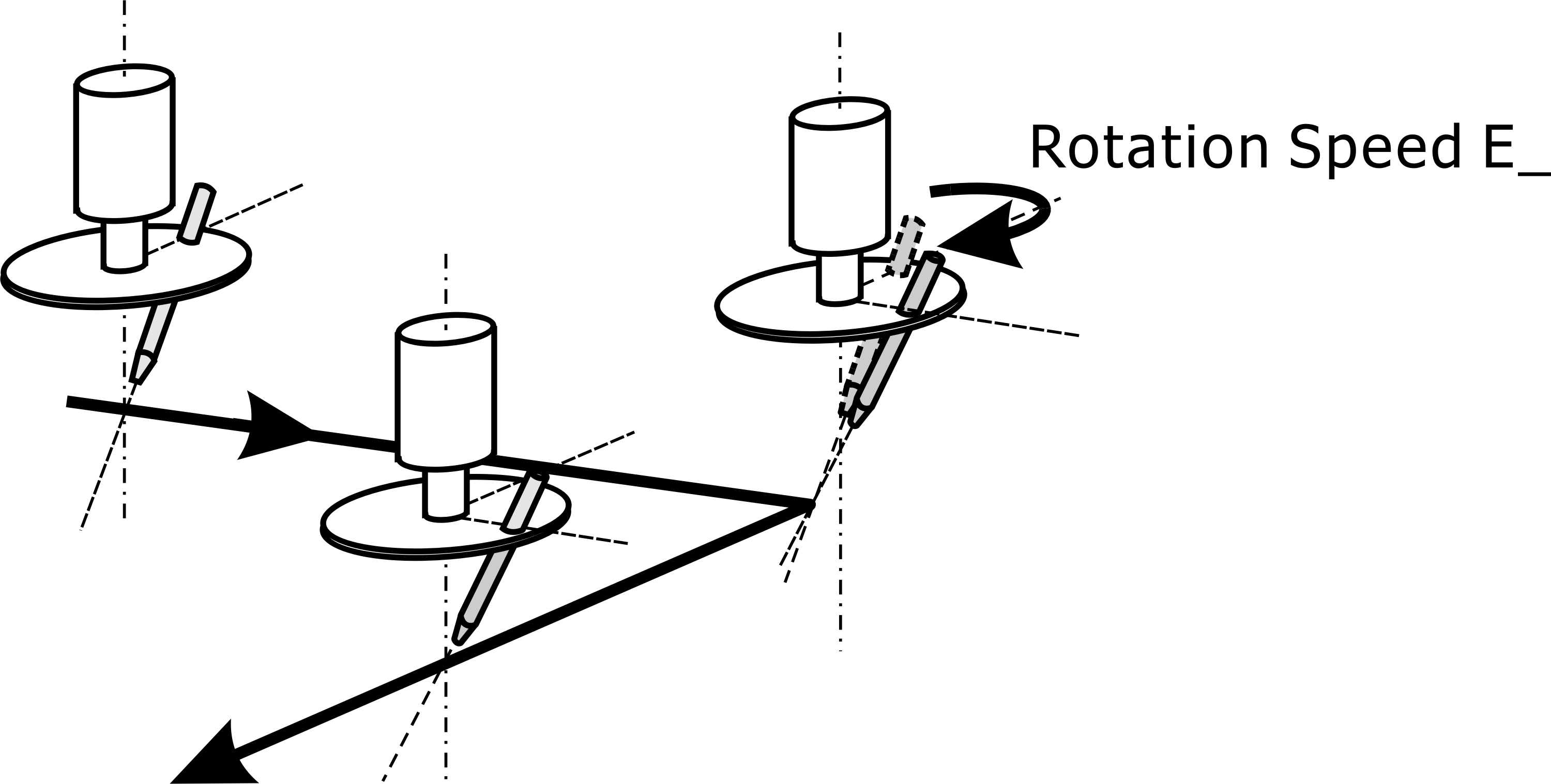

When R_ is defined as the rotation of the fourth axis of the mechanism, the value fed by the servo motor (generally 360 turns, so if this value is not given, it is regarded as 360.000), which is used as the reference for calculating the angle A_ of the preceding paragraph. The following figure shows the path when R_ is 360° and -360° when the starting tilt angle A_ is 90°:

When the starting inclination angle A_ is 90°, the path R_ is 360° and -360°

E_ defines the rotation speed per minute when the fourth axis needs to be rotated in the two linear paths. The definition of this speed is the same as the feed rate for general cutting, in units of the minimum amount of movement on the mechanism.

E_ is the rate at which the fourth axis changes direction