3.5.2 Coordinate Offsets

Coordinate offset system is used to set G54~G59 and additional coordinate offset value, and displays the current coordinate offset value of G92 and G52.

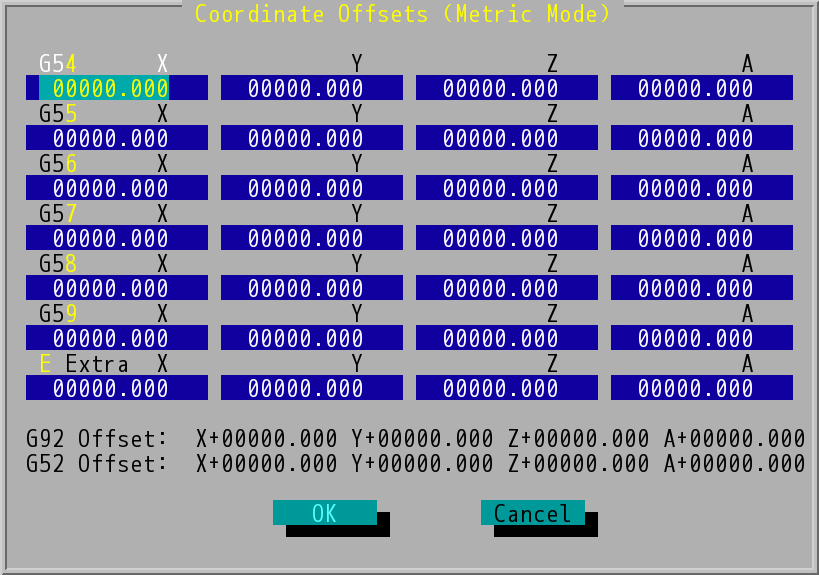

"Coordinate Offsets" Dialog Box (INCON-M84)

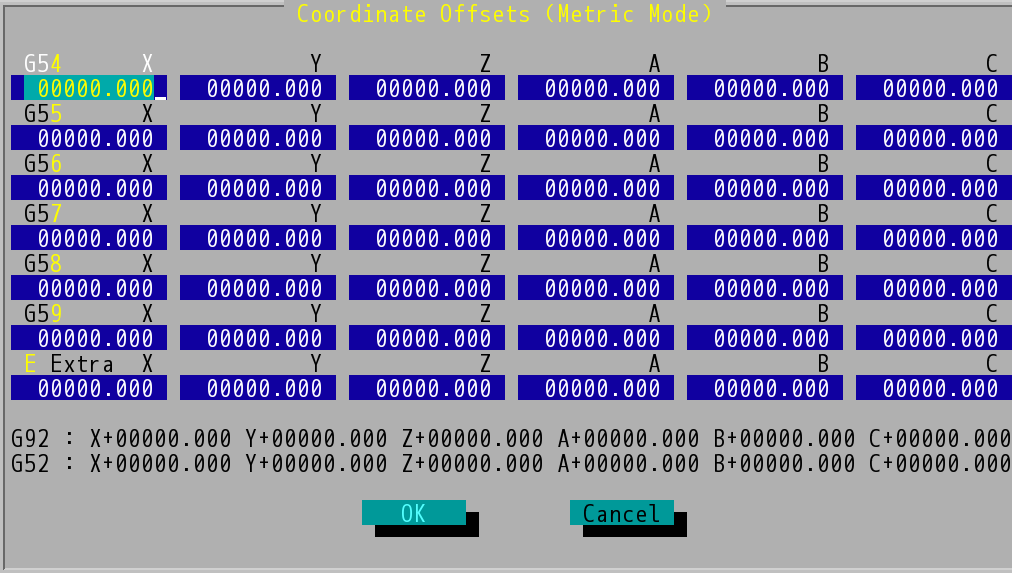

"Coordinate Offsets" Dialog Box (INCON-M86/M86R)

G92 offset and G52 offset are set by G92 and G52 respectively. The lower part of the dialog box is for user's reference, in order to estimate the offset value of each group of work coordinates. G54~G59 program coordinate offset If adding extra coordinate offset in the dialog box, a new G54~G59 coordinate system will be generated. This is usually used to temporarily find the tool with wear but without modifying the program, it will set this extra coordinate offset.

The CNC controller design can assist in setting the work coordinate offset value method, the steps are as follows:

- Move the tool to the origin of pre work coordinate manually first.

- Press "Parameter→Coordinate Offsets" to turn on, and then use TAB key to select each axis field of work coordinate. At this time, pressing F4 key will automatically calculate the axis work coordinate offset value and fill in this field. The program position of this axis will change to 0.

- Use the TAB key to select the other axis offset values for this group and teach it automatically in this way (press the F4 key), then press the ENTER key to save.

- If you want to set the work offset value of other groups, repeat the above steps.

- If F7 is substituted for F4 in the above procedure, the coordinate offset will be calculated by replacing the program position with the relative position, and the relative position of the axis will become zero.