![]() 3.5.14 5 Axes Attribute

3.5.14 5 Axes Attribute

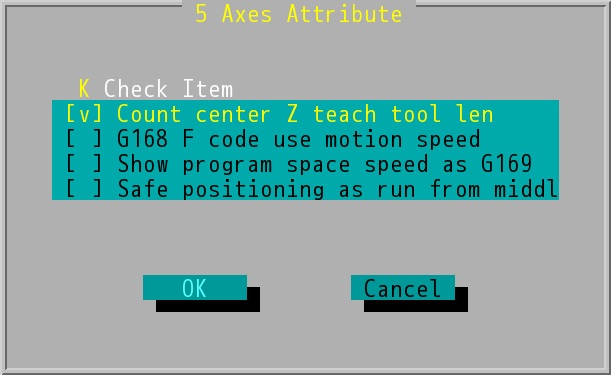

"5 Axes Attribute" Dialog Box

Check Item

[ ] Count center Z teach tool len:

Originally, when the dialog box of "Parameter→Tool Table" was opened, if the F4 teaching length was pressed, the CNC controller will automatically fill in the length field of the Z-axis mechanical position value. If this item is selected, after the "Tool Table" dialog box is opened, press F4 to teach the tool length, the controller will automatically subtract the mechanical position value of the Z axis from the "5-axis rotary mechanism" dialog box of the rotary axis reference surface Z position field set value, then fill in the length compensation field.

When this item is selected, the calculated tool length compensation value when using G37 automatic tool length measurement command will also be subtracted from the Z position of the rotary axis reference plane of the "5-axis rotary mechanism" dialog box in the machine parameter After setting the value of the field, enter the length field of the "Tool Table" dialog box.

[ ] G168 F code use motion speed:

In the original G168 mode, the program specified in the F value for the tip point in the program space speed. If this option is checked, the F value specified in the program in G168 mode is the motion space speed. When this option is checked, the F value displayed in the status window will automatically change to show the speed of the motion space.

[ ] Show program space speed as G169:

If this item is selected, the real speed F_ displayed in the status window will not display the real speed of the motion space in G169 mode, but will show the program space speed. The value of the sts.realVSpeed signal seen by PLC is also the program space speed. If the program has a single block moving B-axis and C-axis, then these sections must be small section of a single section, the value of this speed will be more correct.

Note: Refer to INCON-M84/M86/M86R PLC Manual for PLC signal related instructions.

[ ] Safe positioning as run from middle:

If this item is selected, the behavior first position action of run from middle in G158 or G168 state is following safety process to position.

first positioning action to be performed from the starting behavior G158 or G168 when it was executed is position in the following safety mode:

1. |

Raise the tool up to the limit of the single axis in a normal way. |

2. |

Rotate the rotary axis to the target position from which it is to be performed. |

3. |

Move X, Y, Z to the normal above the target line. |

4. |

Move X, Y, Z and the straight line will be shifted to the target position in the normal direction. |

Please note: This function needs to match the software limits of X, Y and Z axis. If software limit is not set, this function is invalid.

Note: This function applies from system version 5.06E.

- Five-axis machining related G code

G Code |

format |

Function |

G168 |

G168 |

RTCP Open |

G169 |

G169 |

RTCP Close |

G178 |

G178 |

G00 RTCP Open |

G179 |

G179 |

G00 RTCP Close |

G158 |

G158 L_ P_ Q_ R_ X_ Y_ Z_ A_ B_ C_ U_ V_ W_ |

Title plan processing |

G128 |

G128 Q_ R_ |

Tool extraction instruction |

Special M code (M300~M399) does not affect the continuous motion function

INCON-M86R system provides, the use of special M code in the program will not be due to the implementation of M code to stop the movement caused by the smooth axial motion.

The range of special M codes is M300~M399, which can be found in PLC_HSK.H. In the PLC must be given Finish signal immediately, so that M code and S code immediately ended. Special M code must follow G01. If special M code is in a single line, it is the same as general M code.

Program Example:

…

G01 X25.F4000 M399 S5000

G01 X50.F4000

G01 Y25.F4000 M399 S4000