4.7.4.2 G76/G87: Fine Boring Cycle/Fine Back Boring Cycle

Format:

G76 X_Y_Z_R_Q_P_K_F_

G87 X_Y_Z_R_Q_P_K_F_

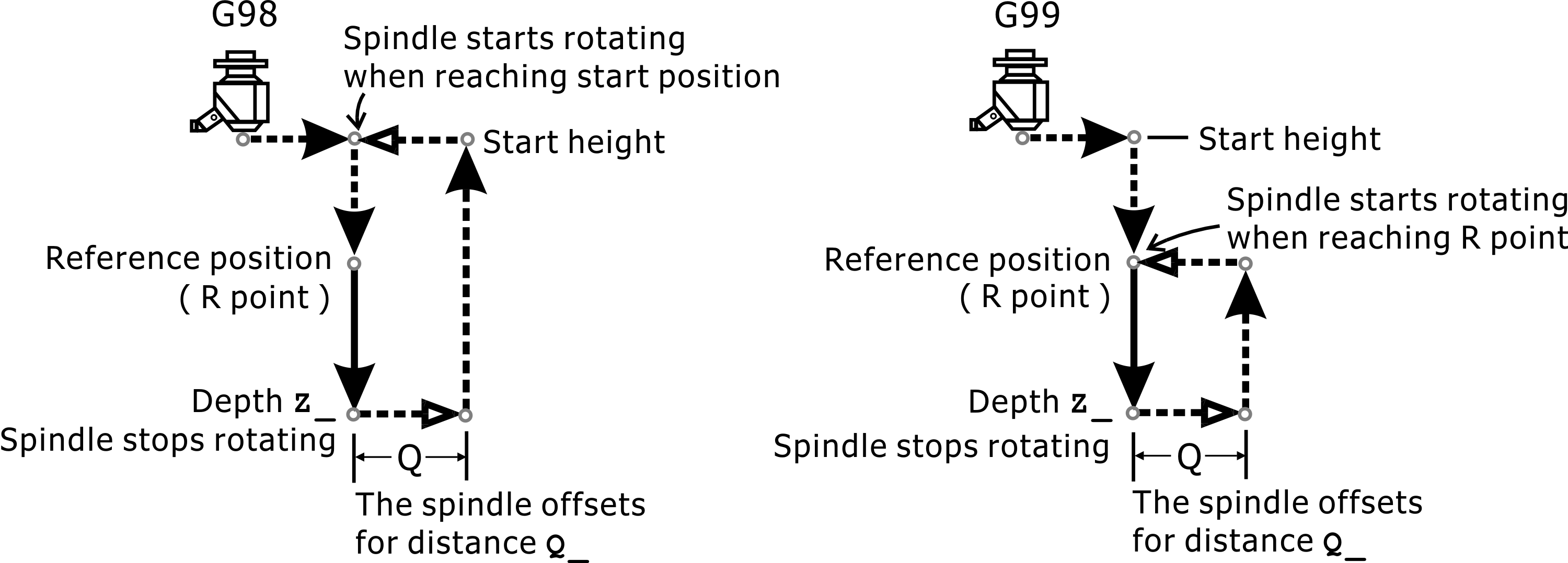

The G76/G87 precision boring holes are all axially specified spindle stops and are therefore precision boring holes. When G76 command is executed, the boring tool is quickly positioned to coordinate point X_Y_, and then it is quickly positioned to the reference height R_ point. After the hole is drilled to the specified depth Z_ at the specified feed rate F_, the spindle orientation is stopped and the tool tip is pointed to after the fixed direction, the center of the boring tool is offset by the Q_ value, so that the tool tip leaves the machining hole surface, and the boring tool is quickly positioned outside the hole to avoid scratching the hole surface. After the boring tool is returned to the original starting height (G98 mode) or the reference height R_ point (G99 mode), the tool center is quickly positioned to return to coordinate X_Y_, and the spindle resumes forward rotation as shown in the following figure.

G76: Fine Boring Cycle

Note: |

The offset Q_ must be positive and its value must not be too large to avoid collisions with the workpiece. |

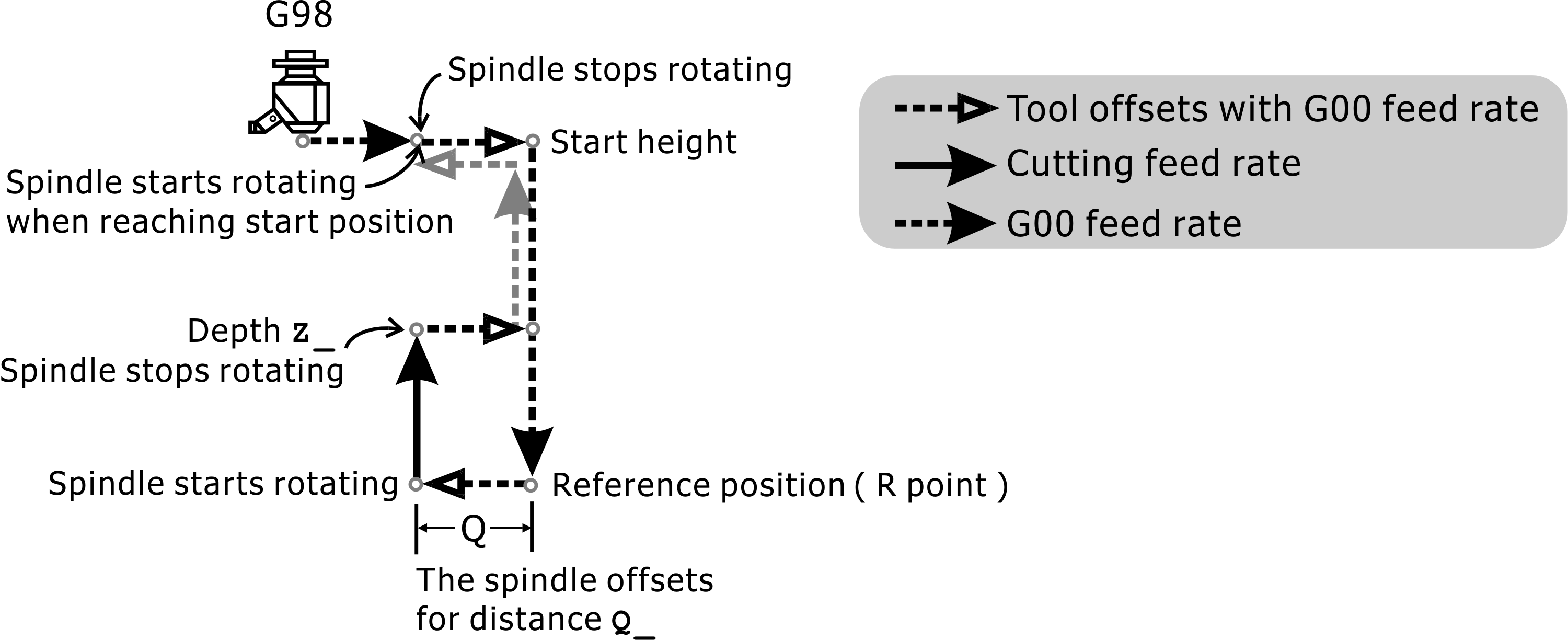

When G87 command is executed, the back boring cutter is quickly positioned to the specified coordinate position X_Y_, the spindle orientation is stopped, the tool tip points in a fixed direction, and the center of the back boring cutter is offset by a small distance Q_ so that the tool tip leaves the machining hole surface. Afterwards, under the tool, to prevent the tool edge from scratching the newly processed hole surface. When the tool moves to the reference height R_ hole bottom, it is offset by the Q_ distance in the original angular direction and then the spindle is resumed to rotate, and the counterboring is started at the specified feed rate F_ to Z_ height. After that, the spindle is stopped orientated, and the tool nose is offset from the machining hole surface to the distance Q_, the tool is raised to the original height, and after the Q_ distance is shifted toward the original angle, the cycle is returned to the original position X_Y_.

G87: Fine Back Boring Cycle

Note: |

The reference position R of the G87 fin reverse boring and the depth of the program Z_ value are different from other cyclic machining. The reference position R point is at the lowest point, and the program Z_ value depth is above the reference position R point. Because its reference position R point is at the lowest point, G87 command is not allowed to execute in G99 mode (back to reference position R point). |