3.2.5.9 Surfacing Machining

Format: G70.06 D_X_Y_Z_U_V_W_C_I_F_

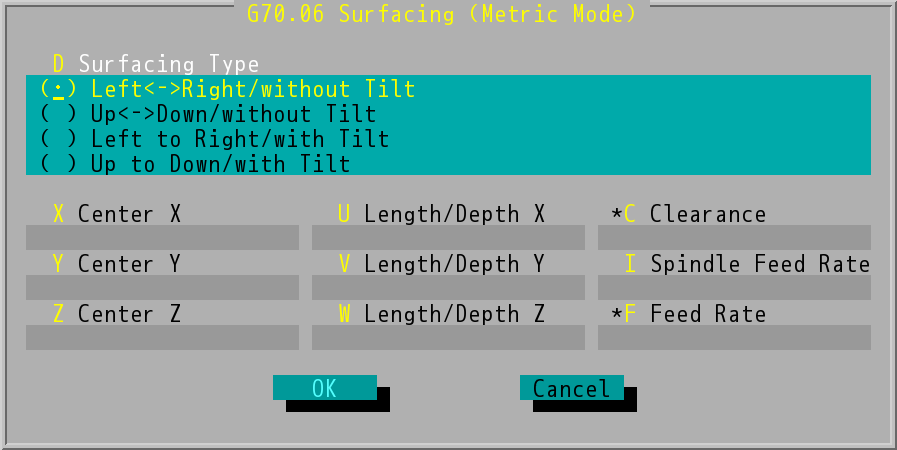

"G70.06 Surfacing (Metric Mode)" Dialog Box

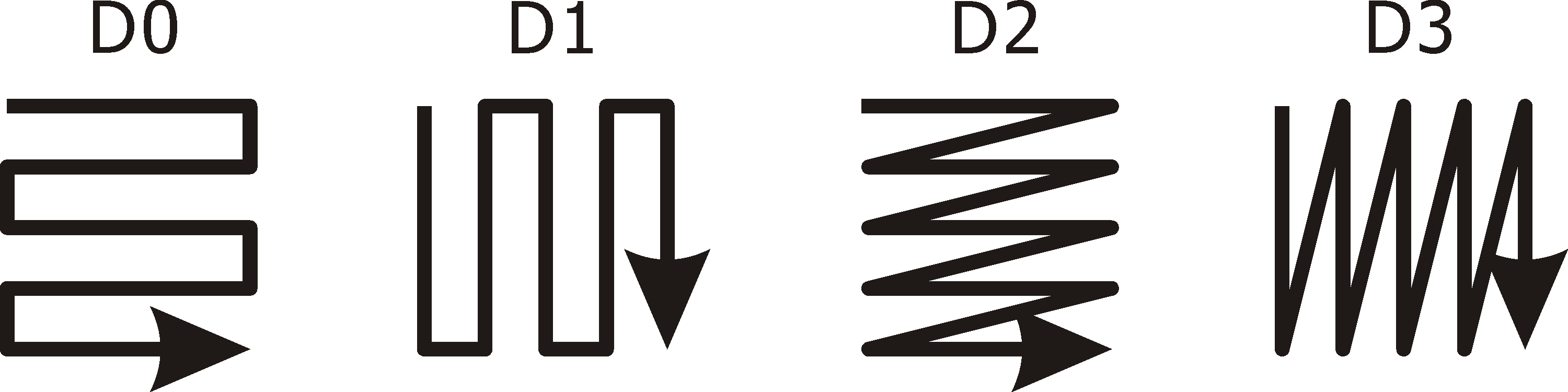

1. There are four surfacing types:

Four Surfacing Types

(1) |

Left ↔ Right/without Tilt (D0) The tool processes surfacing machining by moving along X-axis a distance of Length/Depth X (U value) and then turn to Y-axis, moving along Y-axis a distance of StepInWidth. Next, the tool turns to X-axis and moves along a distance of Length/Depth X (U value) and turn to Y-axis again, moving along Y-axis a distance of StepInWidth. The tool repeats the above procedures until the surfacing machining is finished. |

(2) |

Up ↔ Down/without Tilt (D1) The tool processes surfacing machining by moving along Y-axis a distance of Length/Depth Y (V value) and then turn to X-axis, moving along X-axis a distance of StepInWidth. Next, the tool turns to Y-axis and moves along a distance of Length/Depth Y (V value) and turn to X-axis again, moving along X-axis a distance of StepInWidth. The tool repeats the above procedures until the surfacing machining is finished. |

(3) |

Left to Right/with Tilt (D2) The tool processes surfacing machining by moving along X-axis a distance of Length/Depth X (U value) and then turns back to the opposite direction of X-axis tiltedly. The tool repeats the above procedures until the surfacing machining is finished. |

(4) |

Up to Down/with Tilt (D3) The tool processes surfacing machining by moving along Y-axis a distance of Length/Depth Y (V value) and then turns back to the opposite direction of Y-axis tiltedly. The tool repeats the above procedures until the surfacing machining is finished. |

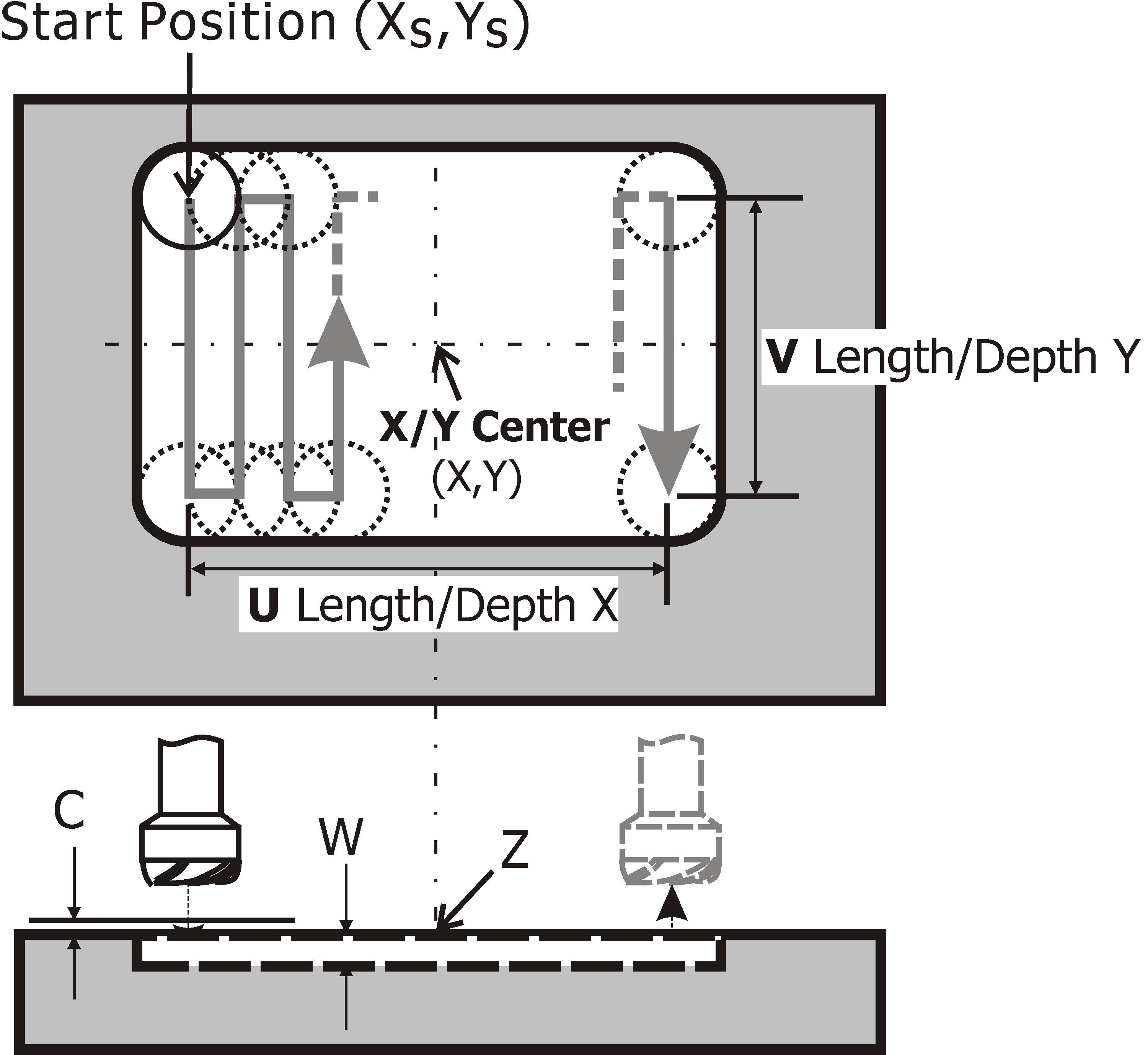

2. The sequence of surfacing machining is below:

(1) |

The tool move rapidly to start position (Xs, Ys) and start height, which is Center Z (Z value) + Clearance (C value). |

(2) |

The tool descends to Length/Depth Z (W value) with Feed Rate (F value) and starts surfacing machining. |

(3) |

When surfacing machining command is finished, the tool ascends to start height and stay at center position Center X/Y (X,Y). |

3. |

The values of Center X/Y/Z (X, Y, Z value) can be absolute positions or incremental values. |

4. |

Length/Depth X (U value) and Length/Depth Y (V value) define the axial length of X-axis and Y-axis. |

5. |

There are four percentage options (150%, 125%, 100%, 75%) for the surfacing width. Users can select from "F2→Parameter→Cancycle Parameters→StepInWidth". |

Surfacing Machining (D1 type)