|

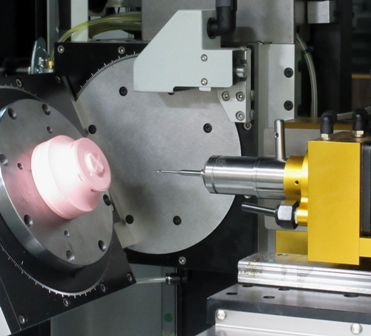

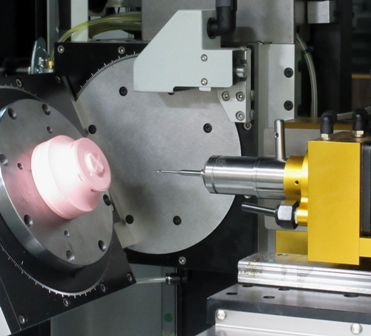

HM5 Horizontal Milling System

Full function horizontal milling machine which is equipped with simultaneous 5-axis motion capability, RTCP and TWP functions. Full function horizontal milling machine which is equipped with simultaneous 5-axis motion capability, RTCP and TWP functions.- Quick and easy tooling change with level spindle design. Equipped with tool probing function. After tooling change, it will automatically measure tool length and update tool compensation table. No need to modify current execute part program.

- The machine is compact and easy for transportation. It can be transported by elevators and it’s equipped with air pump to dissipate heat of workpiece cutting so it’s suitable for working in the office.

- Friendly user interface. It’s built with 15" touch panel, machine panel and waterproof keyboard.

- Ethernet and USB connectivity for data transmission and storage expansion.

- Able to cut plastic, aluminum and bronze.

- Suited for R&D prototype in 3-C mechanism and educational purpose at schools.

Specifications

|

|

Travel of X-axis

|

150 mm

|

|

Travel of Y-axis

|

150 mm

|

|

Travel of Z-axis

|

150 mm

|

|

Travel of A-axis

|

-20~100 degrees

|

|

Travel of C-axis

|

0~360 degrees

|

|

Rapid Traverse of X-axis

|

12000 mm/min

|

|

Rapid Traverse of Y-axis

|

12000 mm/min

|

|

Rapid Traverse of Z-axis

|

12000 mm/min

|

|

Rapid Traverse of A-axis

|

400 RPM

|

|

Rapid Traverse of C-axis

|

400 RPM

|

|

Spindle Speed

|

12000 RPM

|

|

Maximum Tool Diameter

|

4 mm

|

|

Tool Length Probe

|

Contact-type Tool Length Probe

|

|

Positioning Tolerance

|

0.005 mm

|

|

Repeatability

|

0.025 mm

|

|

Panel

|

15’’ Touch Panel / TFT Color LCD

|

|

Dimensions

|

75 cm x 85 cm x 163 cm

|

|

Weight

|

250 KG

|

|

Power Requirements

|

AC 3 phase 220V/50~60HZ, 15A

|

|

|

|

|

Relevant Document

Facebook

|

|

|

Full function horizontal milling machine which is equipped with simultaneous 5-axis motion capability, RTCP and TWP functions.

Full function horizontal milling machine which is equipped with simultaneous 5-axis motion capability, RTCP and TWP functions.